What Fuel Pump Does the 6.7 Cummins Have?

6.7L Cummins diesel engine is famously known for high horsepower and extreme durability, which has caused it to find extensive application in pickup trucks, commercial trucks, and heavy machinery equipment. As one of the core components of a high-pressure common rail diesel engine, the fuel pump plays a significant role in determining fuel supply pressure as well as fuel injection accuracy and directly affects the engine’s performance and life expectancy.

So what fuel pump does the 6.7 Cummins have and what are the differences by model year? In this article, I’ll give you the complete lowdown, including replacement and upgrade recommendations.

Part 1. What Fuel Pump Does the 6.7 Cummins Have? – Quick Answer

The type of fuel pump on a 6.7 Cummins varies by model year:

| Model Year | Fuel Pump Model | Key Features | Common Issues |

| 2007.5 – 2018 | Bosch CP3 High-Pressure Common Rail Pump | Extremely long life, excellent lubrication, highly compatible with different operating conditions | Minor internal wear over time, but overall very long life |

| 2019+ (some models) | Bosch CP4.2 High-Pressure Pump | Lighter weight, better efficiency | More sensitive to fuel cleanliness; susceptible to wear that can cause metal debris contamination |

If you own an older 6.7 Cummins (2007.5–2018), chances are good that it comes equipped with the heavy-duty, battle-tested Bosch CP3, which is greatly prized for reliability and longevity. Newer versions (2019 and up) may use the Bosch CP4.2, which offers efficiency benefits but needs a bit of extra maintenance attention and good-quality, clean diesel fuel to avoid premature wear and costly repairs.

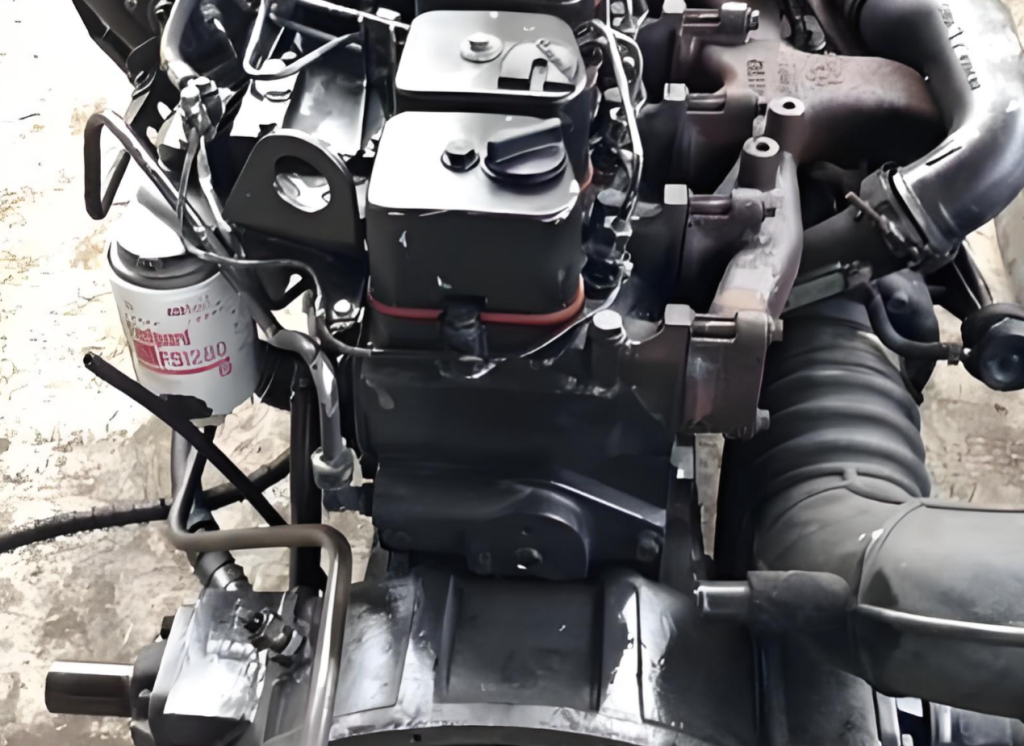

Part 2. What is 6.7 Cummins Fuel System?

The 6.7 Cummins fuel system consists of two main elements: the low-pressure lift pump and the high-pressure injection pump.

The role of the lift pump is to draw diesel from the fuel tank and provide a constant flow into the high-pressure pump so that there’s an ongoing supply for smooth running. The high-pressure injection pump compresses the diesel, typically to more than 25,000 psi, before delivering it to the injectors. This enables precise atomization and timing of the fuel, which are significant to performance, fuel efficiency, and emissions control.

Since the high-pressure pump directly translates to injection accuracy and reliability, its condition plays an important role in injector health as well as overall engine reliability. Various model years of the 6.7 Cummins employ various high-pressure pumps, each with distinct strengths and weaknesses.

Part 3. CP3 vs. CP4 Fuel Pumps — Why the Difference Matters?

While both the CP3 and CP4 are high-pressure fuel pumps that are used in the 6.7 Cummins, they are vastly different in design, reliability, and vulnerability to fuel quality. Knowing these differences matters for owners who want to maintain performance, avoid costly repairs, and choose the right upgrade approach for their truck.

| Feature | Bosch CP3 | Bosch CP4 |

| Typical Model Years | 2007.5–2018 | 2019+ (some models) |

| Design & Size | Larger, heavier, stout build | Smaller, lighter, more compact |

| Durability | Extremely high, tolerant of low-level fuel contaminants | Lower, extremely sensitive to fuel cleanliness |

| Lubrication | Excellent, internal components well-lubricated | Limited lubrication, heightened risk of wear |

| Efficiency | Marginally less efficient | Slightly more efficient pumping |

| Common Issues | Gradual internal wear over long service life | Premature wear can create metal shavings, which ruin injectors and fuel system |

| Owner Preference | Often praised for long-term reliability | Many owners swap to CP3 for peace of mind |

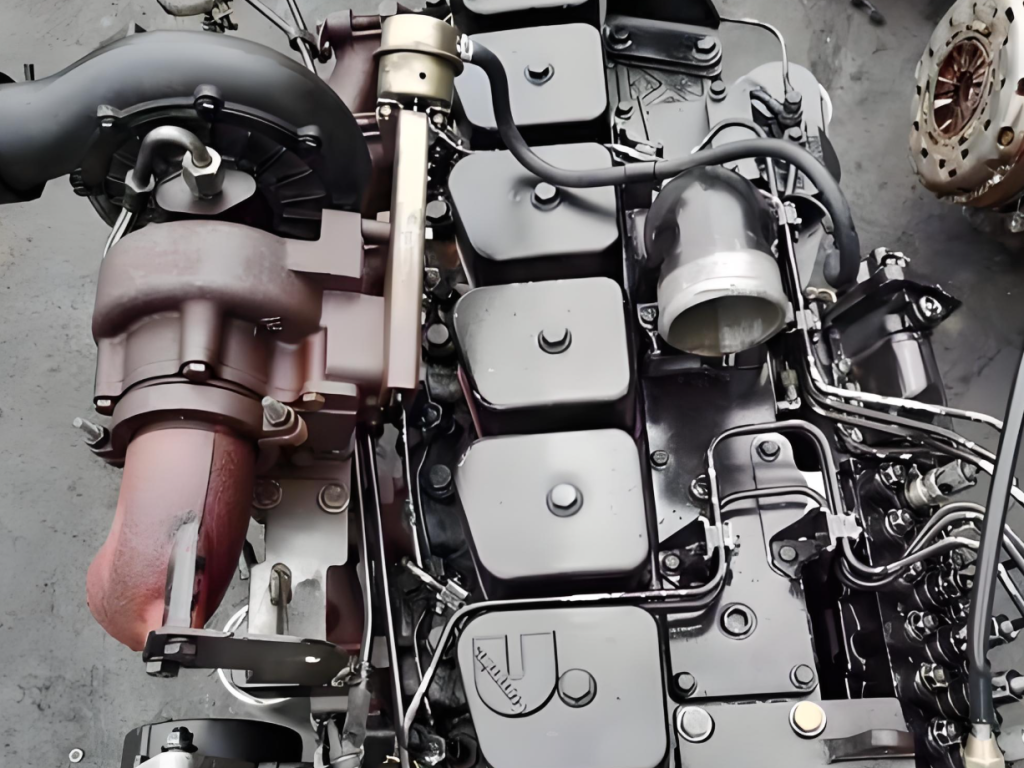

CP3 Fuel Pump

The CP3’s rugged construction and lenient internal tolerances provide it with one of the highest dependability ratings of any high-pressure diesel pump. It provides smooth fuel delivery and is not harmed by small-contaminant damage. Though it is bigger and less efficient than the CP4, its longer lifespan and proven track record make it a good option.

CP4 Fuel Pump

The CP4 was designed to be more efficient and compact to meet tighter emissions and efficiency regulations. Yet its very close tolerances make it far more sensitive to fuel contamination. Even minor wear will allow metal particles into the fuel system, which can destroy injectors and other components—a job which can be incredibly costly.

If your 6.7 Cummins does not have a CP3, you already have a good pump. If it has a CP4, monitor fuel quality and consider a CP3 conversion to increase durability and restrict fuel system failure.

Part 4. Common Issues with 6.7 Cummins Fuel Pumps

The 6.7 Cummins CP3 or CP4 fuel pumps are essential for engine operation. However, over time, there are certain issues that can arise and affect reliability and efficiency:

Metal Debris Contamination

- Most common in CP4 pumps due to very close internal tolerances.

- Wear on the pump can generate microscopic metal shavings, which can circulate through the fuel system.

- Contamination can destroy injectors and other fuel system components, potentially at great cost of repair.

Insufficient Fuel Pressure

- Either through internal pump wear or because the low-pressure lift pump is not delivering enough fuel.

- Low fuel pressure-caused weak injection results in reduced engine power, hesitation, or weak acceleration.

Starting Difficulty

- Usually as a result of worn pump seals, internal wear, or fuel backflow issues.

- Starting with inadequate fueling can cause slow cranking or refusal to start.

Loss of Engine Power

- If the high-pressure pump is not able to supply sufficient injection pressure, combustion efficiency is lost.

- Symptoms include reduced towing capacity, decreased horsepower, and decreased overall engine performance.

Pro Tip: Most issues can be prevented and the life of both the pump and entire fuel system prolonged by regular maintenance, good quality diesel fuel, and prompt replacement of worn parts.

Part 5. 6.7 Cummins Fuel Pump Upgrade and Replacement Recommendations

Choosing the right fuel pump and learning to upgrade or replace it is crucial in maintaining your 6.7 Cummins’ performance and longevity. This chapter offers realistic options, from CP4-to-CP3 upgrades to OEM and high-quality aftermarket replacements, to help you make the right decisions for reliability and fuel efficiency.

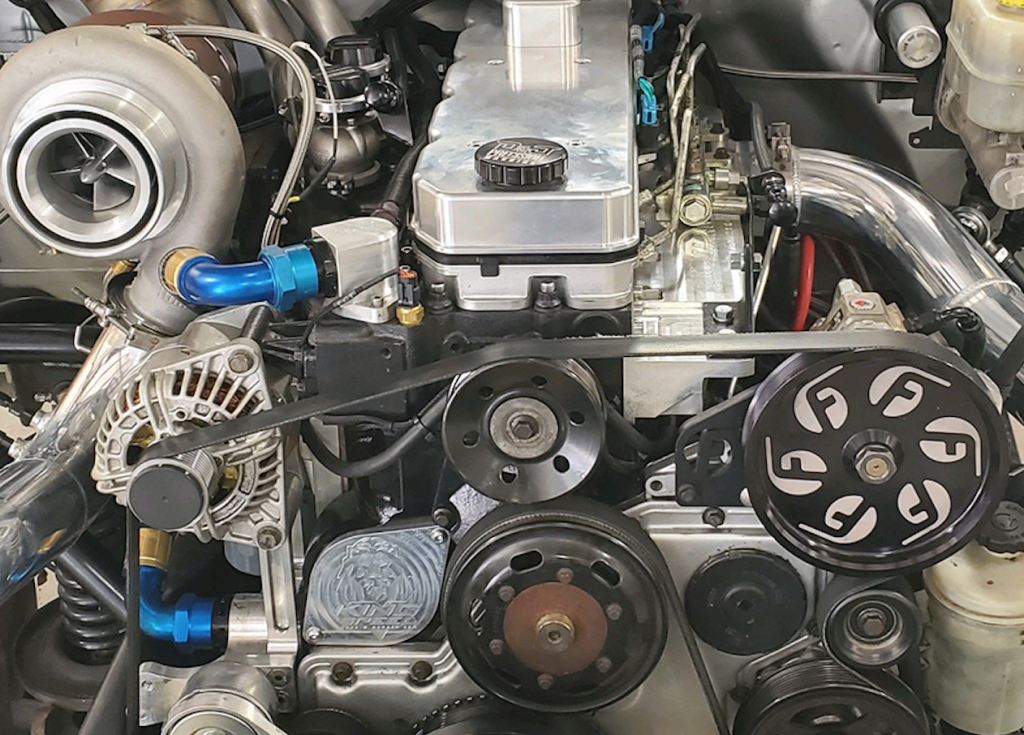

CP4 to CP3 Upgrade

If your 6.7 Cummins engine uses a CP4 pump, a majority of owners will choose an upgrade to a CP3 using a CP3 Conversion Kit.

This upgrade increases strength and reduces the risk of early pump failure or metal shavings contamination, which makes it an ideal choice for high-mileage or heavy-duty truck operations.

OEM Replacement

If replacement of a fuel pump is inevitable, original Cummins or Bosch pumps must be installed.

OEM parts ensure proper fit, compatibility, and long life, maintaining engine efficiency and reliability.

Aftermarket Options

Some high-quality aftermarket fuel pumps can also provide stable performance and may be inexpensive.

Select higher-quality aftermarket manufacturers that equal or exceed OEM quality to prevent reliability issues.

Part 6. Extra Tips for Fuel Pump Maintenance

Proper maintenance of your 6.7 Cummins fuel pump is essential for reliable engine performance and long service life. Here are some tips for maintaining fuel pump:

1. Use High-Quality Diesel Fuel

Always fill with clean, high-grade diesel to prevent contaminants such as dirt, water, or wax from entering the fuel system.

Dirty fuel will accelerate wear on both CP3 and CP4 pumps and may lead to metal debris formation, especially in CP4 models.

2. Replace Fuel Filters Regularly

Fuel filters filter out contaminants before they reach the high-pressure pump and injectors.

Changing filters at the recommended time ensures that clean fuel flow is maintained, the pump is protected, and injection performance is consistent.

3. Avoid Running on Very Low Fuel Levels for Prolonged Durations

Running the system with a very low fuel tank frequently introduces air into the system and can result in cavitation in the pump.

Air pockets decrease lubrication within the high-pressure pump, which may lead to premature wear or failure.

4. Check Fuel Pressure Regularly

Monitoring fuel pressure allows you to spot pump performance issues early.

Pressure loss can indicate wear, leakage, or lift pump issues, so you can address them before engine damage becomes too extensive.

Pro Tip: Proper maintenance, good fuel and filters, will not only keep your fuel pump running a long time, but also optimize overall engine efficiency, power, and reliability.

Final Thoughts

The 6.7 Cummins commonly utilized the heavy-duty Bosch CP3 fuel pump in 2007.5 to 2018 models, while very few models from 2019 utilize the Bosch CP4.2. Regardless of the pump type, proper maintenance and correct replacement can go a long way in extending the life of the engine.

For authentic Cummins fuel pumps, you have Longshine on your side. We provide assurance of reliable sourcing, global shipping, and best solutions for your Cummins engine.