How to Extend the Life of Your Cummins Injector Cups?

Cummins diesel engines are known for their long-term reliability and performance; however, even though engines can experience injector cup failure over time without proper care and maintenance. Injector cups play a pivotal role in sealing fuel injectors against leakage; over time, though heat, corrosion, or incorrect installation could wear away their seal and become compromised, potentially leading to injector cup failure and leaks in fuel injectors.

In this guide, we’ll review some of the causes and solutions behind injector cup failure, best practices to extend their lifespan, signs of wear, and when professional assistance may be required.

Common Causes of Cummins Injector Cup Failure

Cummins diesel engines rely heavily on injector cups as key components that ensure proper sealing between fuel injectors and the cylinder head, helping ensure engine performance issues such as coolant contamination are avoided. Understanding why injector cups fail can help take preventive steps; here are four reasons injector cups typically fail:

1. Excessive Heat & Thermal Stress

Diesel engines operate at high temperatures, subjecting injector cups to intense heat that causes repeated heating and cooling cycles that eventually wear the cups out and lead to warping, cracking, and microfractures in them over time. When cooling systems don’t function effectively due to low coolant levels, failing water pumps, or radiator clogs, excess heat accelerates wear faster. Added stress occurs from aggressive driving or towing as engine temperatures go higher, still putting more stress on injector cups over time.

2. Corrosion from Coolant or Poor-Quality Fuel

Injector cups are typically constructed out of brass or steel and may corrode when exposed to coolant that contains acid or mixes with combustion gases (due to an engine fault such as blown head gasket or EGR issues) causing corrosion on its material surface, weakening and weakening it over time and eventually leading to leaks and structural weaknesses within.

3. Improper Installation or Sealant Failure

One of the leading causes of premature injector cup failure is incorrect installation. If the cups are not seated properly, over-torqued, or installed without the correct sealant (when required), they may not seal correctly. This can lead to fuel leaks, coolant seepage, or even cup movement under engine vibration. Using the wrong type of sealant or failing to follow the manufacturer’s torque specs can also compromise the cup’s integrity.

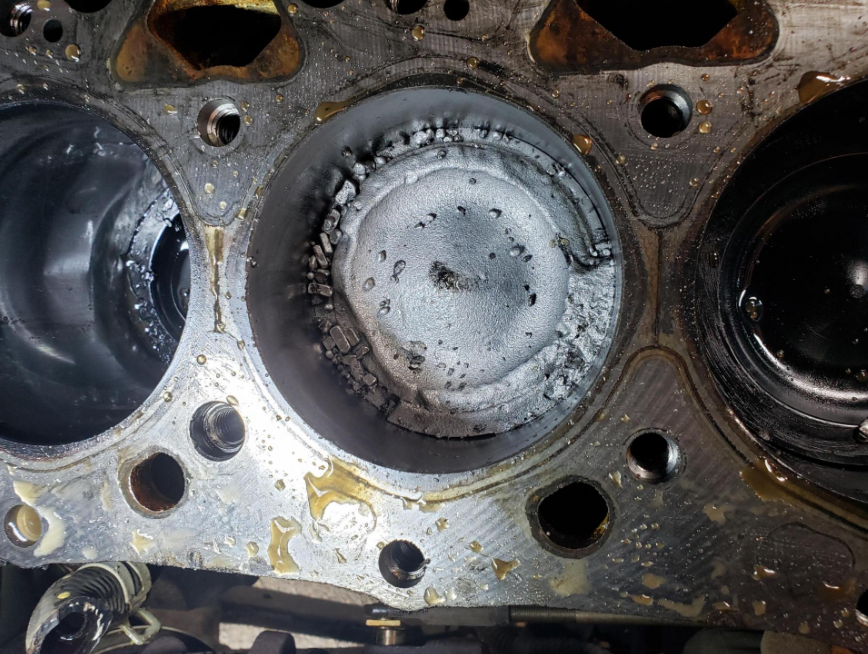

4. Fuel Contamination & Poor Maintenance

Dirty fuel, excessive carbon buildup, or lack of regular maintenance can drastically shorten injector cup life. Contaminants in the fuel system—such as dirt, metal particles, or water—can erode the cup’s sealing surface over time. Additionally, failing to replace fuel filters or ignoring injector cleaning intervals allows debris to accumulate, increasing wear on both injectors and cups.

To prevent injector cup failure, maintain proper cooling system health, use high-quality fuel, ensure correct installation, and follow a strict maintenance schedule. Addressing these issues early can save you from expensive repairs and keep your Cummins engine running smoothly.

Best Practices to Extend Cummins Injector Cup Life

In order to prolong the lifespan of the Cummins injector cups isn’t only about preventing breakdowns, it’s about increasing performance, fuel efficiency and overall engine health. By adhering to a set tested best methods, you can dramatically reduce the likelihood of prematurely failing your injector cup and the expensive repairs that follow it. Here’s how:

Maintain Proper Cooling System Health

The cooling system plays a vital role in regulating engine temperature and protecting internal components–including the injector cups. Overheating is among the most common causes of cup damages, which is often due to a lack of attention to coolant systems.

To avoid this, frequently examine coolant levels and be sure that you are using the right type of coolant as recommended by Cummins. Regular coolant flushes are necessary to get rid of any contaminants that could damage internal parts. Make sure you check for leaks in radiators, hoses and water pumps and take care to address any signs of corrosion or mineral buildup as soon as you notice it.

Use High-Quality Fuel & Additives

Dirty or poor-quality fuel can accelerate wear on your injectors and, by extension, the injector cups. Contaminants in fuel can lead to injector clogging, inefficient combustion, and added stress on cup seals.

Always fill up with high-grade diesel from reputable sources. Consider using diesel fuel additives formulated for Cummins engines to enhance lubrication, prevent deposits, and improve overall fuel system cleanliness. Regular fuel filter changes will also help prevent impurities from entering the injectors.

Follow Correct Installation Procedures

nstallation errors are a common but avoidable cause of early failure of the injector cup. If you’re replacing the cups yourself or with a technician sure that the process of installation is done according to Cummins specs.

This involves correctly tinkering the injectors correctly, effectively cleaning the surfaces that mat, and making sure that the cups are properly seated without excessive tightening. Utilizing OEM or premium aftermarket components is essential for maintaining good sealing and long-term reliability.

Regular Inspections & Preventative Maintenance

Regular maintenance is your first defense against unforeseen injection cup problems. Establish a regular inspection schedule that will check for any signs of wear, leaks or other performance problems.

Be aware of any loss of coolant or fuel contamination. Also, pay attention to changes in the engine’s behavior, like rough idling or misfires. Utilizing diagnostic tools to look for fault codes relating to coolant or fuel injection pressure will also allow you to identify issues early, before they become more serious.

By being proactive and alert by being proactive and attentive, you will extend the life expectancy for your cups and injectors as well as make sure that your Cummins engine will continue to operate at optimum performance.

Signs Your Cummins Injector Cups Need Replacement

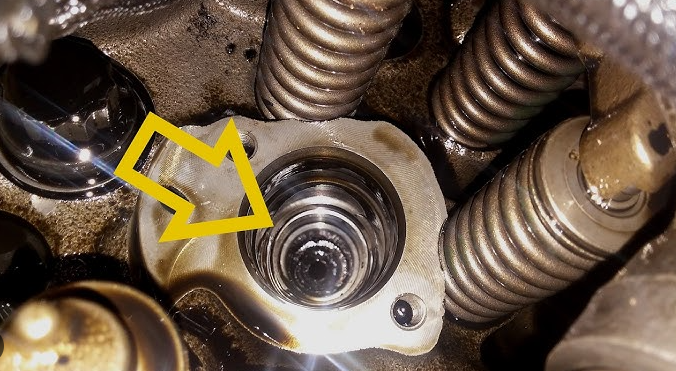

Cummins injector cups

Injector cups are crucial for maintaining a proper seal in your Cummins fuel system, but when they fail, they can cause serious engine problems. Recognizing the early warning signs can save you from costly repairs and downtime. Here are the most critical symptoms to watch for:

1. Fuel Contamination in Coolant

One of the most obvious signs is diesel fuel mixing with coolant, resulting in a milky or oily appearance in the radiator or overflow tank. You may also notice a strong diesel smell from the coolant. This happens when a cracked or leaking injector cup allows fuel to seep into the cooling system.

2. Engine Misfires or Hard Starting

If your engine struggles to start, runs rough, or misfires, it could mean that fuel is not being properly delivered due to a leaking injector cup. Poor combustion from improper sealing leads to power loss and inconsistent performance.

3. Overheating Issues

A damaged injector cup could let coolant escape to the engine’s combustion chamber. This can lead to a decrease in the efficiency of cooling and cause the engine’s temperature to rise. If your temperature gauge is soaring without a clear leak of coolant, check the injector cups.

4. Visible Fuel or Coolant Leaks

Inspect the injectors to find wet spots as well as fuel leakage and white residue (from the burning of coolant). External leaks may indicate a damaged seal, which requires immediate attention.

5. Excessive Exhaust Smoke

Blue or white smoke coming out of the exhaust can indicate fuel burning or cooling inside the combustion chamber. This is a warning sign of an inflator cup problem.

Inattention to these signs can result in hydrolock, major engine damage, or even complete injection failure. If you observe any of these problems, check or replace the injector cups as quickly as you can.

When to Seek Professional Help

Although some diesel enthusiasts like DIY repairs, some problems with the injector cups require professional knowledge. If you are experiencing persistent leaks of fuel around the injectors or suspect that you have a cracked or damaged cup, it’s recommended to seek out a professional. Making repairs without the proper equipment or knowledge can cause improper sealing and further damage to the engine.

Another issue to consider is the possibility of coolant contamination. If your coolant is clear or smells a bit diesel-like, it could be a sign of a serious issue in the injector cup where fuel is interacting with your cooling system. This can affect the performance of your engine, but it can also result in excessive heat and corrosion. An expert can identify the issue, change the cups, or flush out the system to avoid permanent damage.

Finally, if you’ve attempted a replacement but still experience issues, such as hard starting, misfires, or continued leaks, it’s time to contact professional help. If you have any questions, please contact Longshine. Our service team is ready to provide all solutions for your problem!