Common Problems with Cummins PT Fuel Systems and Their Solutions

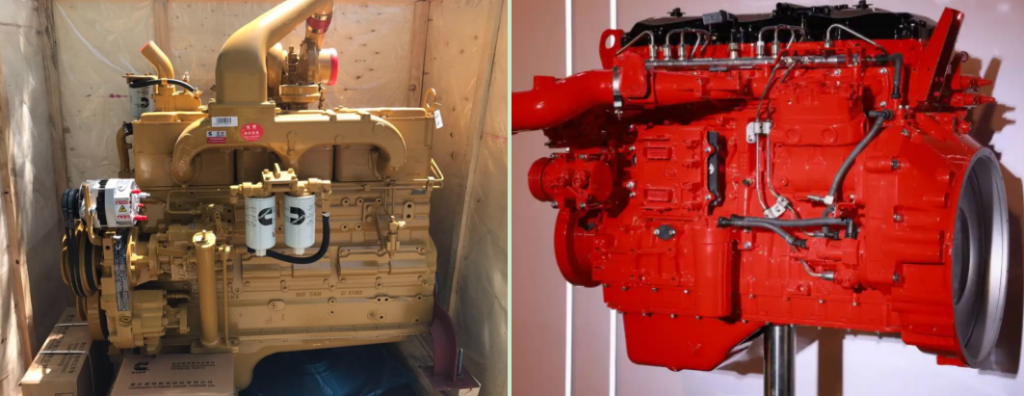

If you own or work with Cummins engines, chances are you’ve heard about the PT fuel system. This unique setup has been around for decades, especially popular in older models, and while known for being tough and reliable, it does have its share of quirks that need addressing. We will compare this system with modern counterparts as well as how its performance stacks up against common issues people run into and provide advice for how you can fix (or prevent!) them.

Cummins PT Fuel System vs. Common Rail

Cummins PT (Pressure-Time) fuel systems differ considerably from modern common rail engines found on newer diesels in terms of their approach and functionality. Instead of using high-pressure fuel stored in an electronic rail with electronically-controlled injectors, PT fuel systems rely on mechanical gear-driven pumps with injectors timed according to engine speed and pressure for timing injections; though seemingly more traditional, it has proven itself reliable over time.

Common rail systems utilize constant fuel pressure with electronic sensors that deliver exact quantities at just the right moment, providing greater fuel efficiency, cleaner emissions, and smoother performance while increasing complexity and repair costs. This results in greater performance efficiency as well as cleaner emissions, but may cause higher repair costs over time.

Generally speaking, PT systems are rugged, easier to work on, and make for superior heavy-duty use; while common rail systems tend to be more energy-efficient but more difficult (and therefore costlier) to diagnose and repair.

Symptoms of Cummins PT Fuel System Failure

When your Cummins engine starts acting up, the PT fuel system is often one of the first places to check. Since it controls how fuel gets delivered to the engine, even small issues can cause noticeable problems.

- One of the more obvious symptoms is difficulty starting, particularly in cold or dormant engines. If it cranks for too long before finally firing up, that could indicate low fuel pressure, air in your system, or worn parts that require replacement.

- Loss of power under load should also serve as an early warning sign; if the engine feels slow or has difficulty climbing hills, improper fuel delivery could be to blame.

- Excessive smoke is also an indicator that something may be amiss – black smoke often indicates excess fuel, while white smoke may indicate incomplete combustion or injector issues.

- Uneven idle and fluctuating RPMs could also indicate pressure regulator or pump wear issues.

- Always perform regular inspections for leaks around injectors, lines, and pumps in your fuel system; leaks waste fuel while simultaneously letting in air into your system and increasing costs.

If you’re seeing one or more of these symptoms, it’s a good idea to start diagnosing your PT fuel system before the problem gets worse.

Common Cummins PT Fuel Systems Problems

Even though the Cummins PT fuel system is built tough, it’s not immune to wear and tear—especially over years of use. Here are the five most common issues you’re likely to run into, what they mean, and how to fix them.

Worn-Out Fuel Injectors

Fuel injectors play a critical role in providing the engine with fuel, but over time, they may become worn out and stop dispensing atomized particles efficiently, resulting in misfires, rough idling, or thick smoke from exhaust pipes. Often, replacing an injector is the solution.

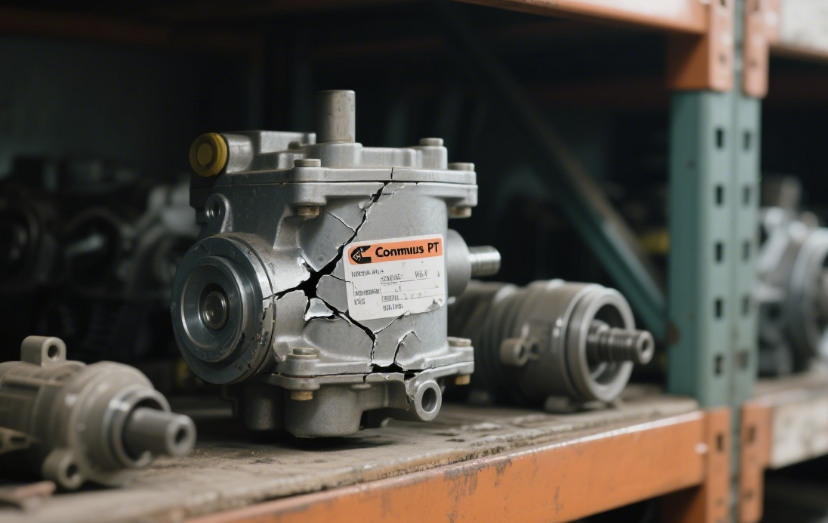

Faulty Fuel Pump mes

A PT pump is at the core of most vehicle fueling systems, and when worn out, it cannot maintain proper pressure for starting, low power, or unpredictable throttle responses. In these instances, a rebuild or full replacement may be required in order to keep things operating as intended.

Air Leaks in Fuel Lines

Air leaks in your fuel system can create all sorts of performance problems- hard starts, surging, or even stalling- and often come from cracked lines or loose fittings. The solution involves tightening or replacing these problem parts before bleeding the system to return to normal function.

Malfunction of Fuel Pressure Regulator

This small component regulates the pressure used to run your system, and if it stops functioning correctly, it could result in irregular fuel delivery, leading to performance and emissions issues that must be managed effectively. Typically, replacing it will rectify this situation.

Contaminated Fuel

Bad diesel, filled with contaminants such as water, debris, or microbiological growth, can clog filters, damage injectors, and ultimately shut off your pump. Changing out for clean fuel is often the solution- always keep filters fresh and regularly empty water separators to help ensure optimal performance!

| Problem | Symptoms | Fix |

| Worn-Out Injectors | Smoke, rough idle, misfire | Replace or service injectors |

| Weak Fuel Pump | Hard starting, low power | Rebuild or replace the pump |

| Air Leaks in Fuel Lines | Surging, delayed start, stalling | Fix leaks, bleed system |

| Faulty Pressure Regulator | Inconsistent power, smoking | Replace regulator |

| Contaminated Fuel | Poor performance, clogging | Clean system, replace filters |

Diagnostic Tools and Tips

Diagnosing issues in a Cummins PT fuel system doesn’t always require a full-service shop, but having the right tools and approach makes all the difference.

- Start by purchasing a fuel pressure gauge. This tool is essential to ensuring the pump and regulator are performing as advertised. Make sure to test both at idle and under load conditions since engine activity may cause pressure levels to dip during these tests.

- If you suspect injector trouble, an injector pop tester is an invaluable asset. This tool demonstrates whether injectors are opening at the right pressure and producing a uniform spray pattern; any misfires, rough idle conditions or smoke caused by malfunctioning injectors would likely indicate this fact.

- Diagnostic scan tools are an essential component of electrically controlled PT systems like CELECT or CELECT Plus. They allow users to quickly read fault codes, sensor data, and rapidly identify any problems. They’re the fastest way to pinpoint issues than guesswork!

- Don’t overlook the basics: A visual inspection can reveal leaks, loose fittings, worn hoses, or fuel contamination issues as well as root causes like air in the lines or a clogged filter.

Pro tip: Always verify fuel quality—bad diesel can mimic a lot of mechanical problems. Start with the simple stuff before replacing expensive parts.

Preventive Maintenance for Cummins PT Fuel Systems

Proper maintenance is key to extending the life and performance of your Cummins PT Fuel System. Since this system relies on precise mechanical components, neglect can quickly lead to costly repairs or poor engine operation. Here are essential preventive steps to keep your fuel system in top condition:

Use Clean, Quality Diesel Fuel

Contaminated or low-grade fuel is a major cause of PT system problems. Always fill up with reputable diesel and consider fuel additives that improve lubrication and prevent buildup. Avoid fuel that contains water or impurities.

Replace Fuel Filters Regularly

Fuel filters collect water and dirt before it gets to the injectors and the pump. Follow Cummins ‘ recommended service intervals to replace filters, thus preventing blockages and damage to injectors.

Inspect for Leaks and Seal Wear

Make sure to check the for leaks in fuel line, sealing, and gaskets to ensure there are no cracks or leaks. Replacing worn seals immediately ensures system pressure and helps prevent fuel loss.

Clean or Service Injectors Periodically

The fuel injectors may develop carbon deposits that can alter spray patterns. Cleanse the injectors with cleaners or have them cleaned by a professional to ensure proper atomization of fuel.

Maintain Proper Fuel Pump Timing

Mechanical timing can affect the accuracy of fuel delivery. Perform timing checks in routine engine maintenance to avoid problems with performance.

By being proactive with these tasks of maintenance, You can prevent numerous frequent PT failures in the fuel system and ensure that your Cummins engine runs efficiently for years to come.

Need Professional Diagnosis?

If you’re having issues regarding problems with your Cummins PT fuel system or require expert advice, it’s a good idea to consult a professional. Longshine is a trusted source that specializes in Cummins engines and spare parts and provides reliable technical support and solutions. If you require assistance in solving complex issues or finding high-quality components, our knowledgeable team will be there for you throughout the process. Trust our knowledge to ensure that your Cummins engine runs optimally and prevent expensive downtime. Do not hesitate to contact!