What Trucks Have Cummins Engines?

Cummins, the global leader in the manufacture of diesel engines, holds a non-displaceable position in the trucking industry. Cummins engines are associated with advanced performance, dependability, and durability ranging from light duty pickup trucks, medium duty delivery trucks, and heavy duty long distance tractors.

Because of this, the question, “What trucks have Cummins engines?” is often asked by many truck owners and business owners as well. This is the question which comes to mind to many. Hence, in this article, we are going to provide you with a complete overview.

Part 1. The Role of Cummins Diesel Engines in Trucks

The ubiquity of Cummins engines in the trucking industry is no coincidence. Through decades of innovation and progress, Cummins became a power source of choice for light-duty pickups, medium-duty transport trucks, and heavy-duty long-haul tractors.

Its prowess comes through in a few major areas:

High Torque Capability: Cummins engines are widely renowned for their exceptional torque capacity, providing reliable performance under heavy loads, hilly terrain and long towing distances – leading to increased productivity and efficiency for logistics businesses.

Fuel Efficiency: With advanced fuel injection technology and optimized combustion systems, Cummins engines are designed to achieve lower fuel consumption. Under long-haul and intensive operations, these savings greatly lower operating costs and improve profit margins for vehicle operators.

Durability and Reliability: With robust frames and wear-resistant components, Cummins engines are crafted to last. They are maintained stable in performance even under extreme conditions such as high temperature, freezing, dusty environment, or excessive use.

Extensive Global Service Network: As a global brand, Cummins has established a broad reach service and parts supply network throughout the world. This provides truck operators and businesses with easy access to maintenance support and genuine parts, minimizing downtime due to engine issues.

For all these reasons, Cummins is not just an engine manufacturer but a complete solution provider that brings together performance, value, and dependability. This is why it has become the powertrain provider of choice for the majority of the world’s leading truck manufacturers.

Part 2. Most Popular Pickup Trucks with Cummins Diesel Engines

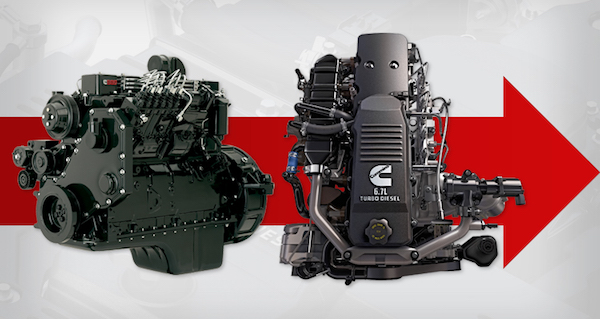

Ram trucks have become synonymous with Cummins diesel engines since 1989 when the first partnership agreement between them and Ram was announced, further strengthening Ram’s competitive edge within the pickup market and further solidifying Cummins’ position as an innovative producer of powerful and long-lasting products.

Representative Models:

Ram 2500 / 3500 — Powered by the legendary 5.9L or 6.7L Cummins Turbo Diesel engines.

Key Advantages:

Unparalleled Towing Capacity: Because of their powerful torque capacity, Ram 2500 and 3500 are capable of withstanding heavy towing duties effortlessly. Whether it is towing motorhomes, boats, or equipment, these vehicles provide seamless and reliable performance.

Outstanding Durability: Cummins engines are designed to be resilient, capable of performing at high levels even in extreme conditions or over extended periods carrying heavy loads. Durability is one of the highest reasons North American truck owners rave so highly about them.

Fuel Efficiency and Savings: In delivering high power, Cummins engines are made with a focus on fuel efficiency, helping drivers and fleet owners save on operating expenses over long distances and everyday driving.

Heritage and Reputation: The intimate connection between Cummins and Ram since 1989 has become inextricably linked with power and reliability. Heritage is also responsible for making Ram pickups retain resale value well when sold used.

To drivers seeking a vehicle that is feasible for everyday use and also possesses heavy-duty towing and hauling capability, Ram pickups fitted with Cummins diesel engines rank among the top options available.

Part 3. Medium-Duty Trucks with Cummins Engines

Cummins engines also reign supreme in the medium-duty truck market as the preferred powertrain for several major brands, including:

- International

- Freightliner

- Hino

Common Engine Models:

- B6.7 — Compact yet powerful engine best suited for deliveries in city limits and short-haul jobs, delivering performance with fuel economy.

- L9 — Offers greater power for hauling medium distances and heavier weights, offering reliable and consistent performance.

Typical Applications

Cummins medium-duty diesel engines are widely used in urban logistics, delivery of courier parcels, and transportation of construction materials. They operate reliably in stop-and-go city traffic and harsh work site conditions, ensuring vehicles stay running smoothly under difficult conditions.

Key Advantages:

Fuel Economy: Advanced fuel injection and combustion design optimization reduces fuel use during extended operation, allowing companies to save on transportation expenses.

Easy Maintenance: With a well-established network of service and readily available parts, Cummins engines minimize downtime and make fleet management a cinch.

Long Lasting in Frequent Stop-and-Go Conditions: Engine build provides toughness and lasting performance despite repeated starts, continuous loads, and aggressive urban or construction environments.

Medium-duty trucks from Cummins engines hence not only raise operational productivity but also provide tremendous advantages in reliability, maintenance, and cost-effective choices for business.

Part 4. Heavy-Duty Trucks Powered by Cummins Engines

For heavy-duty truck business, especially long-haul and heavy-load, Cummins engines are most renowned for their good performance and reliability. They are the powertrain of choice among different top truck manufacturers including:

- Kenworth

- Peterbilt

- Volvo Trucks

- Mack

- Freightliner Cascadia

Common Engine Models:

- X12 — Offers a compromise between good fuel economy and high output, appropriate for long-haul hauls and medium-heavy loads.

- X15 — Delivers robust horsepower and high torque, tailored for heavy loads and long-distance continuous operation, and star powertrain in North American and international heavy-duty trucking markets.

Typical Applications:

Cummins heavy-duty diesel engines are widespread across long-haul trucking, bulk freight haulage, cold chain supply chain management, and other heavy-duty transportation operations. From crossing cross-country routes to handling heavy logistics workloads, Cummins engines make trucks run reliably under heavy-duty operations.

Key Advantages:

Robust Horsepower and High Torque: Provides smooth and effective power delivery even in full load or over long distances, meeting heavy transport’s high needs.

Durability and Reliability: Engine components are designed for durability and wear resistance, capable of withstanding harsh roads and harsh environments with lower downtime and maintenance.

Fuel Economy: Despite their superior performance, the X12 and X15 engines come with optimized burning along with improved fuel injection technology to bring about greater fuel efficiency for lowering the cost of operation.

Heavy-duty trucks with Cummins engines, owing to these aspects, are not only a guarantee of optimal transportation but also an ideal choice for business firms willing to lower operating costs and improve transport reliability.

Part 5. Why Truck Manufacturers Choose Cummins Engines

Truck manufacturers increasingly rely on Cummins engines not only for their better performance but also for their overall capabilities in technology, dependability, and service.

Technological Strengths

Cummins engines possess advanced combustion management and high-efficiency turbocharging technologies to deliver strong power with minimal emissions. This makes them comply with increasingly stringent environmental regulations around the world.

Reliability

No matter driven under hot and dusty conditions, ice conditions, or driven with consistent heavy loads, Cummins engines run reliably. This enables manufacturers to create vehicles that offer long-term reliability and outstanding customer satisfaction.

Wide Compatibility

Light-duty pickup trucks and medium-duty delivery trucks, heavy-duty long-haul tractors – Cummins offers a broad range of engine models so manufacturers can readily match the optimum powertrain with nearly any sort of truck.

International Support

Cummins has established a large global service network and parts distribution system. No matter where a vehicle operates globally, owners can have access to maintenance on time and original parts, reducing downtime and operating risk significantly.

Due to such advantages, truck makers rely more and more on Cummins as their power solution of choice, making their trucks competitive in terms of performance, reliability, and cost of operation.

Part 6. Common Maintenance and Parts Requirements of Cummins Engines

Even Cummins engines with outstanding performance need regular upkeep to stay efficient under harsh operating conditions, in order to remain effective under harsh operating conditions. Proper care not only extends an engine’s lifespan but also decreases downtime and keeps trucks moving more effectively.

Routine Maintenance Parts Used:

Fuel System Parts

Components such as fuel pumps, injectors, and lines play a crucial role in engine power output. Regular checks and replacement are important to ensure consistent fuel delivery, optimal combustion performance, power loss prevention or engine misfire, as well as engine misfiring or engine misfire prevention.

Filters

These include oil filters, air filters, and fuel filters. Filters are effective in removing dust, debris, and impurities and prevent internal engine parts from wear and tear and extend engine lifespan.

Turbochargers

Turbochargers enhance the air flow into the engine for increased power. Overhaul or replacement by regular intervals prevents wear and tear, oil leaks, or breakdown, hence maintaining the engine high in torque capacity and running consistently.

Gaskets and Seals

Seals and gaskets prevent engine oil or coolant leakage and offer an effective seal even at high temperatures and pressures, which is critical for ensuring engine dependability.

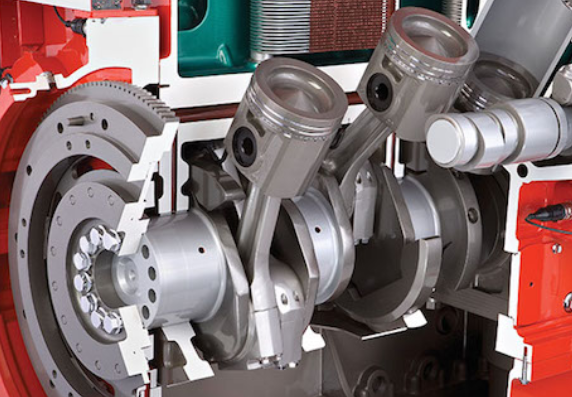

Cylinder Heads

Cylinder heads control sealing of the combustion chamber and exhaust and intake air flow. Compressive stability and high performance are maintained by periodic inspection and maintenance.

Through regular inspections and replacement of major assemblies and routine maintenance, Cummins engines are capable of delivering stable operation during long hours of heavy-duty application, producing reliable power, reducing maintenance costs, and prolonging truck life service.

Part 7. How a Reliable Cummins Parts and Engine Supplier Can Help?

Choosing the right supplier is the most important factor in ensuring the long-term stable performance of your engine. Being a professional Cummins parts and engine supplier, Longshine provides customers with:

- Original replacement parts to ensure compatibility and reliability.

- Cummins engine models with variety to meet various truck and application demands.

- Quick delivery and overseas service to minimize customer downtime.

- Professional technical support to assist with engine maintenance and replacement challenges.

Partnering with an experienced supplier with a comprehensive parts inventory not only reduces maintenance costs but also significantly extends the service life of your equipment.

Final Thoughts

From RAM pickup trucks to the heavy-duty trucks like Kenworth and Peterbilt, Cummins engines are now the preferred power solution of the global transport industry due to their high performance and reliability. When selecting parts and engine dealers for Cummins engines it is imperative that long term operation of vehicles remain stable. Longshine offers high-quality Cummins spare parts and engines at unbeatable prices, offering reliable support from a team of expert professionals.