Cummins Industrial Generator: Reliable Power Solutions for Critical Applications

Every business depends on a reliable energy supply. If that power goes off for example in a hospital, data center, or manufacturing plant, then it’s not just financial costs that will arise but also ones that will involve safety and data loss, and continuity of operations. Cummins, for over a century has been providing these systems solutions, and is known to the World as a more reliable brand than any other enabling products in such harsh conditions. This article will delve into the functions, application scenarios and daily maintenance of Cummins industrial generator, and also introduce how to select the most suitable Cummins industrial generator for you.

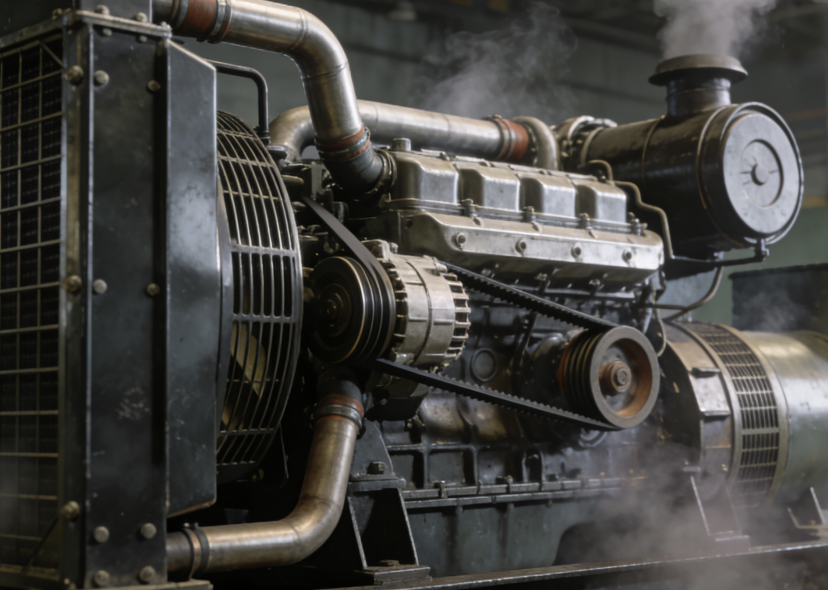

How Does a Cummins Industrial Generator Work?

In its most basic form, it converts various sources of energy into dependable electric power. It starts with a Cummins Diesel Engine where intake air is compressed and used to detonate a fuel charge to produce rotational energy. This energy is used to run an alternator which uses magnets and copper coils to produce Alternating Current which is stable and clean in nature.

That’s where Cummins comes to play. Each and every part from engine to cooling is designed as an integrated unit. The intelligent control system is the brains of the unit which enhances the performance in such a way that the power provided is at optimal levels and hence, this is standard operated as normal for a precise machinery which is equipment. Most of all, this is not a simple generator – this is working reliability.

Cummins Industrial Generator Categories

Cummins doesn’t believe in one-size-fits-all power solutions. Their industrial generators are divided into categories based on power output, fuel type, and use case, so you can find the perfect match for your needs.

By power range

In offices, warehouses or small scale factories, Cummins Industrial Generator 150kW is ideal for providing power outlets during periods of electricity shorting. For the heavier sectors – be it manufacturing or information technology – there are 390kW and 480kW industrial diesel generator units that offer both standby and on-site power generation facilities. These high capacity units allow for several heavy machines to be running all at the same time even during the highest peak period of demand.

By fuel and type

Cummins produces its own types of GI equipment titled as industrial diesel generator and an industrial electric generator. Such models of diesel generators serve as efficient or heavy-duty backup generators or off-the-grid power sources. Such electric models are better suited for indoor usage where both sound and smoke matters a lot. There are some special facilities: for example some generators are designed to be mobile and used on construction sites, additionally, others are silent and used in hospitals, schools or other purpose-built generating facilities with increased efficiency built hybrid electric and diesel generating systems.

The Main Application Fields of Cummins Industrial Generators

The Cummins industrial generators can be found everywhere a power is needed. And many more aspects of the power industry where you would least expect it. Let’s shed some light on the most common areas:

Healthcare

Hospitals and clinics are most vulnerable: If the power goes off in hospitals, everything turns off. Cummins Industrial Generator 480kW are hooked up to the system almost in seconds as they are used to provide power to the life support machines, operating theaters, and drug refrigerators. Special designs also make such generators very quiet, providing good working conditions for the patients and doctors.

Data Centers

Modern servers and storage systems have to remain switched on at all times to prevent lose any data. Cummins industrial electrical generators 480kW keep the power clean and steady, and diesel types are used as a third line of defense should power cuts extend. Multiple racks are quite common to achieve redundancy in many server farms.

Manufacturing

Manufacturing plants need a continuous supply of electricity right from the assembly line to the CNC machines. During power outages, manufacturers ensure their operations do not stop by applying a 390kW industrial diesel generator. This helps avoid unnecessary losses as part of manufacturing processes.

Infrastructure & Construction

In case of road building and mining, and construction sites that are located in remote areas, access to the central grid is impossible. Cummins mobile units are used to generate energy for power tools, lighting systems as well as temporary office structures. Such units were made to endure negative external influences, including high, low temperatures, rattling or dust loading.

Agriculture

On farms and livestock ranches, avoid power drain by setting up generators to supply water for crop lands, in animal enclosures, and silos. The enviro-friendly classics start at -35℃ and yet, provide animals with water and heat effectively replacing electricity.

How to Select the Right Cummins Industrial Generator?

Making a choice of generator is not only about measuring the power of the set but also about considering whether the particular piece of equipment will be used. This suggestion on how to make such a choice should be adhered to.

Estimate the Load to be Powered: Prepare a list of all the equipment that you intend to stimulate, with their wattage ratings. Consider adding 20% to the figure for surges (several units starting at the same time). As in this example of a small factory with a total load of 120kW, a 150kW Cummins industrial generator would be appropriate.

Identify Appropriate Situation for Use: Are you planning on using this equipment for primary or back up purposes? Back up power systems can be designed only to run critical systems while primary power systems must cater for every day full requirements.

Make Allowance for Location and Conditions: If the power generator is located indoors, it should be of the low fume and quiet category. As for Hawking outdoor or remote locations, weatherproof, also construction-type generators may be required.

Assessing energy usage: One of the most important benefits of using an industrial diesel generator with less energy consumption (approximately 200g/k Wh) is cost reduction over time. With Cummins’ PT internal combustion engine having a high combustion efficiency, several problems are avoided within the system.

Maintenance and Troubleshooting of Cummins Industrial Generators

Preventive Maintenance

Regular check-up cannot be compromised. Plan a service for an industrial generator every 250 hours of usage (or once per year based on new units). This involves oil changes, filter replacements, belt and hose examination, and battery check. An important point: An additional supply of Cummins generator components such as filters, spark plug, gasket and others would help a lot with minimizing equipment idle time.

Troubleshooting

If your generator won’t start, check for the fuel levels, ensure all battery connections are in place, as well as see to it that the air filter is free of any dirt—these three components are responsible in most cases. Problems with electricity fluctuations, check if the voltage regulator or the load balance’s condition. Overheating will commonly be a result of a blocked radiator or facing circulation of the coolant; a case clean the radiator and add the required fluids immediately. In case this still happens, it is best to call an industrial generator service company and avoid taking further action yourself particularly for complicated components.

Cummins Industrial Generator Price

The cost of industrial generator vs Cummins generator is based on the capacity of the output, configuration and astigmatism compensation feature. Below is a basic guide for rough estimation;

It is possible to buy a Cummins industrial generator of 150 kW for about $15,000 to $25,000. It is equipped with basic control unit and regular housing. Industrial diesel generator of 390 kW Compressive force displacement and right from $40,000 to about $60,000 depending on sound mitigating features and high definition monitoring devices.

An industry strength power unit a generator for a power rating of 480kW costs between $70,000 and $120,000. The cost of these gensets, hybrid or backup systems, will be on the upper end, or even beyond, this scale. The cost of routine Cummins generator parts and industrial generators maintenance can be brought under control by taking a service contract.

Why Choose Cummins Industrial Generator

The diesel generator market is crowded with brands. So, why should it be Cummins?

First of all, engines by Cummins run without any embarrassment of operating them over 10,000 hours. As long due to Modular design most of the repairs are within operators’ reach and Cummins generator parts can be found easily in almost any corner of the earth.

Secondly, fuel economy in Cummins diesel generators is as good as 191 grams per kilowatt hour saving operational costs. There is an specially designed system composed of SCR and DPF which exceeds the emissions levels required by EPA Tier 4 for example.

Thirdly, Cummins Industrial Generator has more than 6,000 dealer and service centers providing industrial generator support worldwide. Quick and efficient industrial generator repair and genuine parts are available no matter where your company conducts its work from.

Additionally, Cummins has various options including the option of quiet enclosure and remote controlling systems. Their auto detection solutions help expect problems before they happen and are capable of being tracked by a mobile phone or a computer.

FAQs

Q1: How often should I service my Cummins industrial generator?

A1: For standby use, service annually or every 250 operating hours. For continuous use, service every 100 hours. Always follow the manufacturer’s schedule for industrial generator service.

Q2: Where can I find genuine Cummins generator parts?

A2: The most reliable source for genuine Cummins generator parts includes authorized dealers, Cummins’ global parts network, and trusted suppliers like Longhsine.

Q3: What’s the difference between a standby and prime generator?

A4: Standby generators (like industrial backup generator 480kW units) activate only during outages. Prime generators run as the primary power source for off-grid or continuous use.

Q4: How long will a Cummins diesel generator last?

A4: With proper maintenance, a Cummins generator can last 20-30 years. The engine lifespan is typically 10,000-30,000 operating hours, depending on use.

Q5: Can I install a Cummins industrial generator myself?

A5: We don’t recommend it. Cummins generators need professional installation to ensure safety, proper wiring, and compliance with local codes. Authorized dealers handle installation, so you’re covered if something goes wrong.