How to Program Fuel Injector on Cummins?

When replacing or servicing fuel injectors in a Cummins diesel engine, injector programming is a key procedure. The majority of users find it difficult to deal with issues such as idle instability, excessive emissions, or loss of power following injector replacement. The root cause is often in the fact that they cannot enter the injector trim codes correctly.

Here, we are going to provide an accurate description on how to program a fuel injector on Cummins, the required tools, common issues, required precautions, and where to buy reliable Cummins fuel injectors, so that you can attain maximum engine performance. Let’s get started!

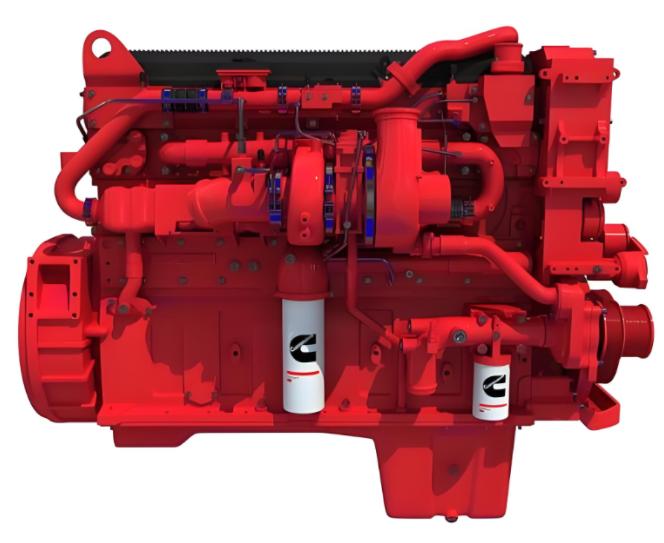

Part 1. What is Cummins Injector Programming?

Injector programming is the process of entering the trim code (also known as a calibration code) for each Cummins fuel injector into the engine’s Electronic Control Module (ECM). These codes define each injector’s individual flow rate differences. From this data, the ECM will precisely control the quantity of fuel injected into each cylinder for optimal combustion efficiency and emissions performance.

Each injector has a unique trim code, typically printed on the injector itself, tagged as a label, or retained in a QR code. Inputting the correct trim code allows the ECM to compensate for slight manufacturing tolerances between injectors, ensuring balanced engine running and maximum performance.

Part 2. When is Cummins Injector Programming Needed?

Injector programming is required in a variety of standard circumstances. It ensures that the ECM correctly identifies and controls each injector to its own specifications. The engine will experience performance or emissions issues if not programmed.

Replacing One or More Injectors: When installing new or rebuilt OEM aftermarket injectors, each injector’s trim code must be programmed into the ECM for proper fuel delivery.

Shifting Injector Installation Locations: When CPS injectors are relocated to other cylinders during servicing, their trim codes must be updated to reflect the new positions. The ECM requires dependable cylinder-to-code associations to function optimally.

Reflashing or Replacing the ECM: While replacing the ECM or reflashing its firmware, pre-existing injector calibration data may be deleted which will require reprogramming.

ECM Fault Codes Indicating Calibration Issues: In all instances where the ECM is generating fault codes about missing or mismatched injector information, it is usually essential to reprogram the injectors to rectify the situation.

After Major Engine Rebuild or Protracted Inactivity: In engines that have undergone a complete overhaul or have been inactive for a prolonged period, programming of the injectors ensures safe engine start-up and efficient engine performance.

Part 3. How to Program a Fuel Injector on Cummins?

Step 1. Preparations Before Programming the Fuel Injector on Cummins

Before performing injector programming, it is recommended to prepare the following tools:

- Cummins INSITE diagnostic software (genuine version recommended for full functionality)

- Vehicle diagnostic interface, such as Nexiq USB Link or Inline 6

- Injector trim codes, usually 6- or 8-digit numbers (some may come with a QR code)

- Stable power supply, ensuring voltage does not drop below 12V

Important Notes:

- Do not disconnect power or unplug any interface during the programming process

- Ensure each injector’s trim code matches its corresponding cylinder number

- It is recommended to perform programming in a clean and dry environment

Step 2. Connect to the ECM

After all the preparation is complete. It’s time to connect to the ECM now. Use a diagnostic interface to connect your computer to the vehicle. Launch the Cummins INSITE software, select the appropriate engine from the list, and establish communication with the ECM.

Step 3. Identify Injectors and Cylinder Numbers

Record the trim code for each injector and match it with the corresponding cylinder. This step is crucial to avoid assigning the wrong code to the wrong cylinder.

Step 4: Access the Programming Menu

In INSITE, navigate to the Calibration or Fuel System section. Look for the option labeled Injector Trim Codes or a similar name and open the input interface.

Step 5: Enter the Trim Codes

Input each trim code according to its matched cylinder number. Double-check all entries before clicking “Write” or “Save” to update the ECM.

Step 6: Save and Restart the Engine

Upon saving modifications, disconnect the diagnostic interface and begin monitoring the engine. Subsequently, check for any irregular codes or unusual behaviour that would indicate successful programming.

Part 4. Common Issues and Troubleshooting Tips on Programming Fuel Injector

Here we outline common problems users encounter when programming Cummins fuel injectors, along with practical troubleshooting tips.

| Problem | Possible Cause | Recommended Solution |

| Engine shaking or rough idle | Incorrect or missing injector trim codes | Verify that all injector trim codes are correctly entered into the ECM. Re-enter codes if necessary. |

| ECM error “Injector mismatch” | Injector trim codes do not match the cylinder installation order | Double-check the physical installation order of injectors and ensure each trim code corresponds to the correct cylinder. Reprogram if needed. |

| The injector label is missing, damaged, or worn out | Injector label is missing, damaged, or worn out | Contact your supplier or manufacturer to obtain the correct trim code information or replacement labels. Avoid guessing codes to prevent engine issues. |

Part 5. Types of Programmable Injectors in Cummins Engines

Cummins engines equipped with electronically controlled fuel systems and coded injectors generally support injector programming. Below is a comprehensive list of models:

1. Modern Electronically Controlled Engine Series (Support Injector Programming)

- ISX Series (e.g., ISX15, ISX12)

- QSB Series (e.g., QSB4.5, QSB6.7)

- QSM Series (mainly used in industrial and generator applications)

- ISL Series (e.g., ISL9, ISL G)

- ISB Series (e.g., ISB6.7)

- X12 and X15 Series (newer models with advanced electronic controls)

- L9 Series

These engine series are equipped with Cummins Electronic Control Modules (ECMs) that support entering injector trim codes and precise calibration.

2. Traditional Electronically Controlled Engine Series (Partial Injector Programming Support)

- NT855 Series (e.g., NT855-C, NT855-M)

- NTA855 Series (turbocharged variants)

- K Series Engines (e.g., KT19, KTA38, KTA50, commonly used in heavy equipment)

- M Series Engines (e.g., M11, M11 CM)

These engines support injector programming if equipped with an ECM and coded injectors; however, some older models may have limited programming capabilities or lack fine calibration features.

3. Some Early or Older Engine Models

Early mechanical fuel systems or engines without an electronic control module (e.g., certain older N Series and K Series engines)

These models typically do not support injector programming since they lack ECMs to store and apply injector trim codes.

Part 6. Where to Buy Cummins Fuel Injectors with Trim Codes?

Longshine is a professional supplier of Cummins engine parts with expertise in providing genuine fuel injectors. The fuel injectors will ensure maximum engine performance, improved fuel economy, and environmental protection with adherence to emission standards.

Serving a long list of clientele that includes repair shops, dealers, and end users, Longshine provides bespoke solutions to fit the correct injector models to the relevant Cummins engines. In addition to providing quality parts, Longshine also offers comprehensive technical support to lead customers through proper installation and calibrating fuel injectors.

Committed to quality and customer satisfaction, Longshine sources injectors from quality manufacturers and subjects each unit to rigorous quality control. Their sales and technical personnel, with many years of experience, are more than happy to offer professional advice on injector selection and offer competitive quotations.

For anyone seeking quality Cummins fuel injectors with full support, Longshine presents itself as a serious partner, dedicated to helping customers maintain engine efficiency and reliability.

Final Thoughts

Although fuel injector programming is not a mechanical assembly process, it is an important step in the maintenance of newer electronically controlled Cummins engines. By entering the individual trim code of each injector, the ECM can accurately meter fuel injection, ensuring fuel efficiency, reduced emissions, and extended engine life.

If you are interested in purchasing Cummins injectors or require technical support, please contact Longshine. We are ready to provide you with a one-stop parts and service solution.