How to Bleed Injectors on 5.9 Cummins 24 Valve?

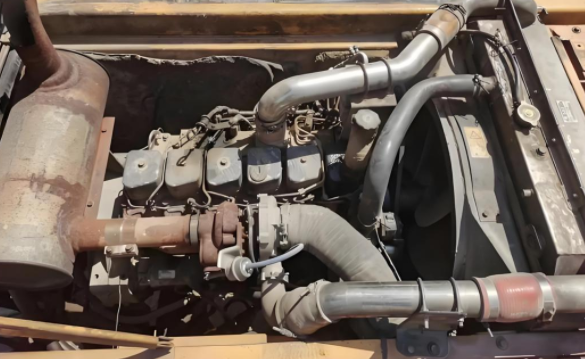

The 5.9 Cummins 24 Valve is often called a true “workhorse legend.” From highways and heavy-duty trucks to farms and construction sites, it runs hard year after year while still delivering reliable power. But even the most dependable engine can be tripped up by a small issue—air entering the fuel system.

Don’t underestimate a little air. It can cause the engine to crank repeatedly without starting, leaving operators frustrated and losing valuable time. If you want to bring this classic diesel back to life quickly, understanding how to bleed injectors on 5.9 Cummins 24 valve is a crucial step.

Part 1. Why Does Air Enter the Fuel System of a 5.9 Cummins 24 Valve?

Under normal operating conditions, the fuel system of the 5.9 Cummins 24 Valve engine should remain completely sealed. A completely sealed system helps to maintain a balanced fuel pressure. The fuel pressure is what is required to inject the fuel accurately. As long as there is air in the system, the pressure will not remain balanced. This will interfere with the appropriate fuel atomization.

In real-world situations, the condition of air intrusion occurs in the following cases:

1. Incomplete Bleeding After Injector Replacement

When replacing injectors or removing high-pressure fuel lines, air can easily enter the fuel passages. If the system is not properly bled afterward, trapped air may remain inside the injector lines or injectors themselves. Because diesel injection relies on high fuel pressure, the compressibility of air reduces injection force and can significantly impact starting performance.

2. Fuel Filter Replacement Without Pre-Filling

Replacement of the fuel filter is an essential routine maintenance procedure. In some cases, if the fuel filter is installed without being pre-filled with diesel, then during engine start up, some air may remain inside the fuel filter housing. As a result, the engine will either take more time to start up or may not start.

3. Weak or Failing Lift Pump

The lift pump supplies the necessary fuel to the high-pressure injection system. In the event that the lift pump becomes worn out, weak, or unable to maintain necessary pressure levels, it could result in an unstable flow of fuel. In fact, it could sometimes result in a slight vacuum effect that may suck in air into the system if the fittings are not perfectly tightened.

4. Aging Fuel Lines or Sealing Components

Over time, O-rings, copper washers, and fuel line fittings can harden, deform, or develop small cracks. Even minor sealing issues may allow air to enter the system. In diesel engines, slight negative pressure conditions can pull air in without necessarily causing visible fuel leaks, making the problem harder to detect.

Part 2. Common Symptoms of Air in the Injectors

When air enters the fuel system of a 5.9 Cummins 24 Valve, the injectors cannot deliver diesel at consistent high pressure, which directly affects engine performance. Typical symptoms include:

1. Difficulty Starting the Engine

The presence of air lowers fuel pressure, preventing proper atomization. As a result, the engine may require multiple cranks to start or may fail to start entirely.

2. Cranks but Won’t Start

Even if the starter motor operates normally, the engine may not ignite. This happens because the high-pressure injectors cannot deliver fuel continuously and evenly into the combustion chamber, preventing stable combustion.

3. Noticeable White Smoke on Cold Start

Air in the system can cause delayed or incomplete fuel injection, leading to incomplete combustion. On cold starts, this often results in visible white smoke, especially in low-temperature environments.

4. Unstable Idle or Engine Shaking

Even after starting, air in the injectors can cause uneven fuel supply, leading to rough idling or engine vibration. The engine may feel unsteady at low speeds or while idling.

5. Reduced Power

Air trapped in the high-pressure fuel system reduces combustion efficiency, leading to decreased engine output and slower acceleration. The effect is more noticeable under heavy load conditions.

6. Fluctuating Fuel Pressure

Air bubbles in the fuel system create pressure variations between the fuel pump and injectors. This may show up as fluctuating fuel pressure on the gauge or unusual pump noises, indicating unstable fuel delivery.

If problems persist after performing how to bleed injectors on 5.9 Cummins 24 valve, further inspection may be required:

- Check the injectors for leaks or internal wear

- Verify that the fuel pump is delivering consistent pressure

- Inspect fuel lines and connections for proper sealing

A thorough check ensures that the fuel system is free of air and the engine returns to stable, reliable operation.

Part 3. How to Bleed Injectors on 5.9 Cummins 24 Valve?

Before starting, ensure a clean work environment and prepare the necessary tools and safety gear. The following steps explain how to properly bleed injectors on a 5.9 Cummins 24 valve and remove trapped air from the fuel system.

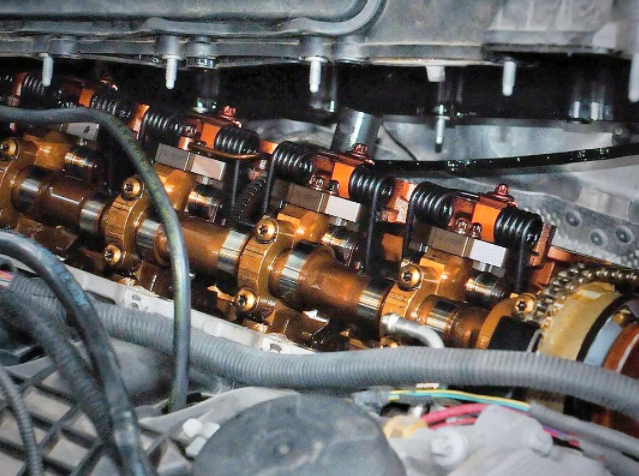

Step 1. Loosen High Pressure Fuel Line Fittings

Generally, it is suggested that the process should be done starting from the front and moving towards the back. Loosening the injector connections requires caution, with an eye to preventing damage to the threads and the injector itself.

Fuel spillage should be anticipated and measured accordingly. This step works to unleash and evacuate air from the engine when cranking.

Step 2. Crank the Engine for Short Intervals

Run the starter to crank the engine slightly, enabling fuel to be supplied through the high-pressure lines. Air will be pushed out along with the fuel supply. However, avoid long cranking, which may cause depletion of the battery charge and overheating of the starter motor.

Step 3. Observe Fuel Flow

Watch the fuel at the line connection for a steady, bubble-free flow. If bubbles are still visible, the air has not been fully removed, and the bleeding process should be repeated. A continuous, steady flow indicates the air has been successfully expelled.

Step 4. Retighten the Fuel Lines to Specified Torque

Once a stable fuel flow is obtained, a torque wrench is then used to tighten any high-pressure fittings that require it, as specified by the manufacturer. This prevents damage to any threads as well as any type of fuel leak.

Step 5. Repeat for All Injectors

Each injector should be bled individually until the entire system is free of air. For engines equipped with a VP44 fuel pump, make sure the fuel supply pressure is sufficient, as inadequate pressure can allow air to re-enter the system.

Important Safety and Operation Tips

- Keep fuel lines and fittings clean to prevent contaminants from entering the fuel system.

- Control cranking intervals to avoid overworking the starter or draining the battery.

- Tighten fittings to the recommended torque to prevent leaks or thread damage.

- Ensure the fuel pump is functioning properly, especially on VP44-equipped engines, to guarantee effective injector bleeding.

Following these steps ensures the engine can start normally, fuel system pressure is stable, and power output returns to reliable levels. Properly knowing how to bleed injectors on 5.9 Cummins 24 valve is essential for maintaining engine performance and avoiding recurring fuel system issues.

Part 4. What to Do if Problems Persist After Bleeding Injectors?

Even after a bleeding operation through the injector, it is still possible that the engine may experience problems with hard starting, rough idling, or reduced engine power output. It is believed that there could be underlying problems in the engine’s fuel system, which cannot be solved through further bleeding.

1. Internal Injector Leaks

A worn or failing injector seal or valve can cause fuel to return or reduce pressure, preventing consistent fuel delivery. Even after bleeding, air can still enter the system through these leak points.

2. Poor Fuel Atomization

A clogged or worn-out injector nozzle could cause problems in the distribution of fuel or fuel atomization. Air could be trapped in the chamber or in the fuel lines, which could affect the engine’s starting ability.

3. Insufficient Lift Pump Pressure

The lift pump pumps fuel to the high-pressure system. Lack of sufficient pressure will result in unstable circulation of fuel, leading to probable air leaks that prevent proper function of high pressure injectors.

4. High-Pressure Fuel Line Wear or Micro-Cracks

The high-pressure fuel lines may eventually have minor signs of wear or cracks. These minor imperfections in the lines could cause air to leak into the fuel system, which might eventually mean that problems return despite proper bleeding of the injectors.

5. Aging or Failing Seals

The seal of the O-ring, copper washer, and fuel line fitting may be lost over time. The usage of inferior quality seal materials will cause problems of repeated air intrusion, which may affect the power of the engine.

If the issues persist with the above steps of the How To Bleed Injectors On 5.9 Cummins 24 Valve process, then all the injectors, fuel pump, high-pressure fuel line, and seal must be inspected. In the long run, good fuel system parts must be sourced. Good fuel system parts are those that meet the standards of the original equipment manufacturer. Good fuel system parts will guarantee smooth engine ignition and performance.

Part 5. The Importance of High-Quality Fuel System Components

The 5.9 Cummins 24 Valve engine requires high precision in its fuel system, especially in the coordination between the injectors and the VP44 fuel pump.

High-quality components typically offer the following advantages:

- Precision machining to ensure stable fuel pressure

- Optimized nozzle design for consistent fuel atomization

- Reliable sealing to minimize the risk of air intrusion

- Durable materials capable of withstanding high pressure and corrosion

- High compatibility with the original factory system

In equipment used in a continuous system for commercial or industrial purposes, long-term stability is considered more important than short-term savings. Using good-quality fuel injection equipment or components may significantly prevent failure and increase its life.

We, as a global supplier of Cummins parts, are to deliver genuine parts of OEM quality that perform satisfactorily under different conditions of operation.

Summary

It is important to know how to bleed the fuel injectors on the 5.9 Cummins 24 valve engines, which are diesel-powered. But more important is the reliability and quality of the diesel fuel system and its components as it originates.

However, when there is frequent access to the fuel system by air, then the problem may not be just an operational issue, as worn injectors, a weak lift pump, and old seals could be factors.

As a result, for users around the world running 5.9 Cummins 24 Valve engines, it is the choice of good-quality fuel system components that can ensure long-term stable running.

With proper maintenance and good-quality spare parts, the classic engine is guaranteed to give the performance and reliability for which it was built.