Cummins Marine Engines: Everything Need to Know Before Choosing

In the global marine power industry, Cummins has earned widespread trust for its outstanding performance, exceptional reliability, and comprehensive after-sales support. From fishing vessels and tugboats to cargo ships and offshore engineering vessels, Cummins marine engines are renowned for their efficiency, durability, and stability, providing reliable power solutions for all types of ships. If you are looking to learn more about or purchase a Cummins marine engine, this article offers a clear, comprehensive guide.

Part 1. What is a Cummins Marine Engine?

Cummins is among the top manufacturers of engines in the world and has almost 100 years of experience in diesel power technology.

A quality Cummins design also combines innovative design and performance engines with reliability in the harshest marine environments.

Cummins marine engines are widely used in:

- Commercial vessels (such as cargo ships, ferries, and tugboats)

- Fishing vessels (such as deep-sea fishing boats and refrigerated processing ships)

- Recreational boats and yachts

- Offshore and defense vessels (such as offshore operation ships and patrol boats)

Besides propulsion engines, Cummins manufactures auxiliary power systems and marine generator sets to meet the varied demands for power, efficiency, and environmental performance in every vessel type.

Part 2. Main Series of Cummins Marine Engines

Cummins provides a complete range of marine engines spanning from light recreational craft to heavy industrial marine vessels. For your reference, here are some of the primary series of Cummins marine engines:

1. B & C Series (QSB6.7 / QSC8.3)

- Power Range: 250–600 HP

- Typical Applications: Small commercial vessels, yachts, fishing boats

- Features: Compact structure, low noise, and electronic fuel control for better fuel efficiency.

This series is suited for small to medium-sized vessels. The comfort, performance, and economy of the series ensure a vessel owner’s optimal satisfaction. Its compact structure facilitates installation, and the advanced fuel management system guarantees better fuel economy and cleaner combustion.

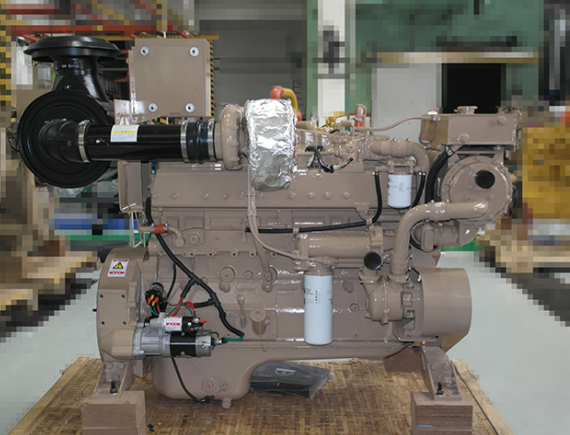

2. M Series (QSM11)

- Power Range: 300–715 HP

- Typical Applications: Medium passenger vessels, trawlers, workboats

- Features: An electronic control system, cleaner combustion, and stable performance.

The QSM11 is a reliable mid-power option, known for consistent performance and very good fuel efficiency. Its strong build and accurate electronic management make it a popular choice for vessels requiring dependable power with moderate displacement and endurance.

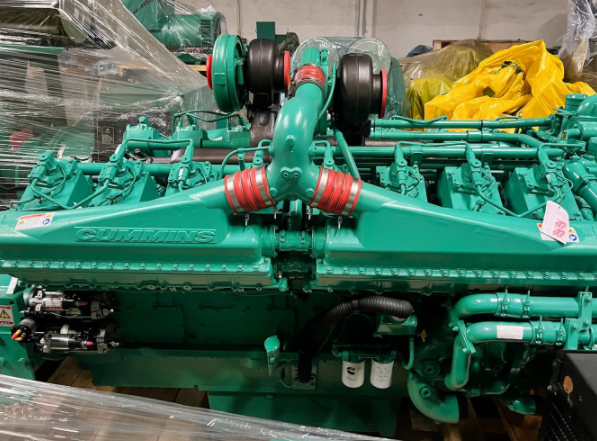

3. K Series (K19 / K38 / K50 / KTA19 / KTA38 / KTA50)

- Power Range: 425–2200+ HP

- Typical Applications: Tugboats, cargo ships, offshore engineering vessels, nearshore operation ships.

- Features: Heavy-duty design, durable mechanical construction, long service life, and ease of maintenance.

The K Series represents Cummins’ classic high-power marine platform. Designed for heavy-duty and continuous operation, it is widely trusted by commercial and industrial shipowners worldwide. Its proven reliability and robust torque output make it suitable for demanding marine operations.

4. N Series (N855 / NTA855-DM)

- Power Range: 300–450 HP

- Typical Applications: Fishing boats, barges, auxiliary power systems

- Features: Mechanical fuel injection, high torque, easy maintenance, and low operating costs.

The simple, robust construction makes N Series a favorite among old or retrofitted vessels. It has been considered a “workhorse” for those shipowners seeking reliability and long-term durability without sophisticated electronics.

5. QSK Series (QSK19 / QSK38 / QSK50 / QSK60)

- Power Range: 600–3200 HP

- Typical Applications: Large commercial ships, offshore supply vessels, military ships

- Features: High-pressure common rail electronic fuel system, IMO Tier III emission compliance, high fuel efficiency.

QSK Series is the pinnacle of Cummins marine technology. Engineered to power modern vessels with optimal performance and fuel economy, while addressing specific environmental concerns, it sets new boundaries through its advanced electronic control and emission standards for the most demanding operations anywhere in the world.

6. Auxiliary and Marine Generator Series

- Representative Models: KTA19-G, QSK38-G, QSX15-G

- Applications: Shipboard power supply, auxiliary engines

- Features: Stable output, optimized fuel consumption, low maintenance costs.

These engines and generator sets assure reliable electrical power on ships, supporting propulsion systems. They find wide applications for onboard electricity, auxiliary machinery, and backup power; thus, all vessel operations run smoothly with high efficiency and low operating cost.

Part 3. Key Benefits of Cummins Marine Engines

Cummins marine engines are trusted worldwide not only for their performance but also for the comprehensive advantages they bring to shipowners and operators:

The reason for the global confidence in marine Cummins engines stems not only from their efficiency and quality but also from the numerous overall benefits they offer to ship owners and operators.

1. High Fuel Efficiency

With the use of advanced fuel injection technologies and engines’ fuel combustion systems designed for maximum fuel use efficiency, Cummins engines improve fuel consumption, enable extended cruising ranges, and lower operational costs.

Most of these models have an electronic engine management system for real-time adjustments of fuel supply and super effective efficiency fuel control within various load conditions.

2. Exceptional Durability

The engines’ key components, constructed from highly resistant electrochem corrosion alloys and high-strength castings, ensure engines withstand harsh marine environments, including high salinity and humidity, and continuous heavy load conditions.

This high-quality marine hull engine construction and robust castings lower the frequency of major repairs and ensure extended service life of the engine, making it ideal for commercial, offshore, and industrial applications.

3. Stable and Reliable Performance

Cummins marine engines have been confirmed through millions of hours of sea operation with excellent start-up and continuous operational performance. They keep the torque and power output stable even when the load fluctuates in order to guarantee reliable propulsion and auxiliary power for any vessel type.

4. Environmental Compliance and Emission Standards

Almost all Cummins marine diesel engines aid shipowners in complying with international legal emission standards such as EPA Tier III and IMO legal emission standards, while also decreasing fuel emissions and diesel standards.

Engines fitted to such vessels are of growing importance to shipowners as they are endorsed for vessels of growing importance for sustainable and environmentally friendly use.

5. Global Service Network and Parts Support

Cummins’s service network ensures ships are supported with genuine Cummins parts and qualified technical Service and Support, ensuring customers receive the required Service and Support necessary to achieve specified performance.

Global service provides customers with reduced service and support turnaround times to ensure sustained operational readiness of vessels for local and international coastal and high seas routes.

Part 4. How to Choose the Right Cummins Marine Engine?

In pursuit of optimal performance, efficiency, and reliability, the right Cummins marine engine should take into consideration and evaluate in no particular order.

1. Vessel Type and Application

The power and performance requirements of different vessels differ. For instance:

Commercial ships require a very high power for continuous operation.

Fishing vessels require engines with strong torque for hauling and stability during long operations.

The operation of passenger vessels and yachts requires smoothness, quietness, and economy.

Large engines rated to withstand heavy environments and widely fluctuating loads are quite common in offshore and engineering vessels.

Understanding the vessel’s primary function is the first step in selecting the right engine series and model.

2. Power and Torque Requirements

Assess the propulsion needs of the main engine and the electrical load of auxiliary systems.

Propulsion Power: Determines the vessel’s cruising speed, maneuverability, and towing capacity.

Torque Requirements: Ensures that the heavy loads, or sudden changes in resistance, do not overload the engine.

Correct calculation of these parameters will avoid underpowered engines and excess fuel consumption due to over-sizing.

3. Operating Conditions

Consider how the engine will be used:

Continuous Duty: Applications that run the engine for extended periods either at steady or variable loads call for heavy-duty models with a very effective cooling system and lubrication.

Intermittent Duty: Engines with shorter operational cycles or variable workloads can prioritize efficiency and lighter maintenance.

Matching the engine to its duty cycle will ensure longevity and performance consistency.

4. Emission and Environmental Regulations

Compliance with international and local emissions standards such as IMO Tier III and EPA is highly critical. Meeting or outperforming such standards by selecting the appropriate engine will support not only regulatory compliance but also provide added value in terms of environmentally friendly and economic solutions.

5. Maintenance and Support

Select engines from brands and channels that offer reliable access to spare parts, technical service, and global support. A well-supported engine minimizes downtime and ensures smooth operations, particularly for vessels operating far from home ports.

Part 5. Importance of Maintenance and Genuine Parts

The operational reliability of a marine engine depends on effective maintenance using quality genuine Cummins parts. Maintenance on a scheduled basis not only optimizes performance but also extends an engine’s lifespan and minimizes expensive downtimes. For any marine diesel, the following upkeep practices are essential:

1. Oil and Filter Replacement

On a scheduled basis, engine oil and filter changes reduce internal components from wear and tear, maintain efficient lubrication, and prevent the engine from developing sludge. The use of genuine oil filters from Cummins ensures complete compatibility and protection of essential engine components.

2. Examination of Cooling and Fuel Systems

To prevent an engine from overheating, corroding, or developing scales and ultimately losing performance, the cooling system requires regular maintenance. For optimal combustion, the fuel system and all components of the fuel system, including lines, pumps, and tanks, of the engine also require regular maintenance to prevent leaks, fuel contamination, or blockages.

3. Rectification of Injector Calibration and Clearance

Adjusting the injectors determines the amount of fuel that maintains the combustion and the amount of emissions. The regular check and adjustment of the valve clearance promotes smooth running of the machine, reduces wear, and ensures reliable starting and running of the machine under a range of drop loads.

4. Replacement Parts From the Original Manufacturer

By replacing the worn-out or damaged parts with those from Cummins, the engine can safely and reliably meet the required performance and emissions and remain within the set limits. Original replacement parts are crafted to the same standards as the genuine parts, which significantly lowers the chances of the parts failing and prolongs the life of the replacement part.

Reliability, fuel efficiency, and safety of operation in hostile aquatic environments are fundamentally determined by genuine parts and unswerving maintenance.

Part 6. Why Choose Cummins and Longshine?

Partnering with Cummins engines and Longshine ensures that your vessel reaps the benefits of both world-class marine power and professional, reliable support. Here’s why shipowners and operators choose us:

Decades of Specialized Experience: Longshine has long specialized in Cummins parts and Cummins marine engines for sale.

Comprehensive Inventory: We maintain an extensive inventory of Cummins engines and their parts, covering models ranging from light recreational units to heavy-duty industrial engines.

One-Stop Technical and After-Sales Support: From technical consultation, engine selection, spare part provision, to after-sales support, we offer one-stop solutions!

Competitive Pricing and Fast Delivery: We pride ourselves on offering fair, competitive pricing as well as efficient logistics that guarantee that engines and parts arrive on time.

Reliable, Efficient, and Cost-Effective Solutions: Longshine offers efficient Cummins power solutions that are reliable and cost-effective, whether that is complete engine purchases or just parts replacement for existing marine engines.

Final Thoughts

Cummins marine engines have long been recognized for their powerful performance and high quality, making them an essential component in marine power systems around the world. From small fishing vessels to large engineering ships requiring main propulsion or auxiliary systems from main propulsion to auxiliary systems, Cummins engines provide cost-effective solutions with minimum environmental impact.

Longshine provides existing stocks, professional technical support services to guarantee the delivery of Cummins engines as well as genuine parts to every customer, ensuring every journey goes safely without worry or delay.