Cummins Industrial Engines: How It Drives Your Business Forward?

In power generation systems, construction machinery, and heavy machinery, “power” has long been synonymous with reliability and efficiency. Of the leading brands in the industry, Cummins industrial engines rank among the most reliable power options. At the forefront of fuel efficiency, greater durability, and cutting-edge technological innovation, Cummins offers tough, reliable power to industries worldwide.

Part 1. What Are Cummins Industrial Engines?

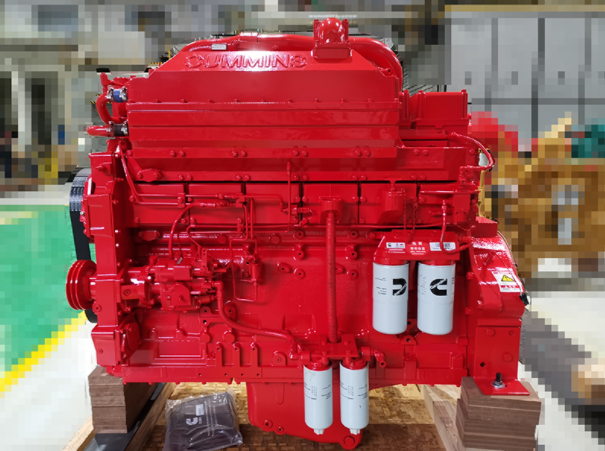

As it was founded in 1919, Cummins Inc. is a leading worldwide producer of diesel and alternative-fuel power systems. Cummins industrial engines mostly define engines for off-highway use, such as construction equipment, farm equipment, mining equipment, marine power units, and industrial generator sets.

Generally, they are defined by:

- Robust build to withstand tough operating conditions

- Long-lasting and dependable power output

- Optimum fuel efficiency

- Compliance with global environmental emission standards (e.g., EPA Tier 4 and EU Stage V)

With advanced engineering expertise and a global after-sales support infrastructure, Cummins has become the preferred power partner for the majority of equipment makers worldwide.

Part 2. Key Technologies and Advantages of Cummins Industrial Engines

Cummins has always been the leader in industrial power technology, never relenting in creating engine technology to deliver more performance, reliability, and environmental integrity. Through decades of research and proven application, Cummins has built a range of record-breaking technologies that are redefining the boundaries of industrial power.

1. High-Pressure Common Rail Fuel System (HPCR)

The HPCR system provides precise electronic control of fuel injection pressure and timing that results in peak combustion efficiency, quieter engine operation, and reduced vibration and noise. With more complete combustion of the fuel, the technology not only increases power but also reduces fuel consumption and unwanted emissions, both environmentally and economically.

2. Advanced Aftertreatment Technology

Cummins implements a number of emission control technologies—EGR (Exhaust Gas Recirculation), DOC (Diesel Oxidation Catalyst), DPF (Diesel Particulate Filter), and SCR (Selective Catalytic Reduction)—to ensure absolute compliance with the world’s most rigorous environmental regulations, such as EPA Tier 4 Final and EU Stage V.

Cummins’ full system minimizes nitrogen oxides (NOx) and particulate matter (PM) to the best degree to help equipment operators attain green operation levels without any compromise on performance.

3. Smart Electronic Control Module (ECM)

The ECM is the “brains” of the engine, detecting temperature, pressure, and load conditions in real time at all times. The ECM dynamically manages fuel flow, turbo boost, and timing specifications to optimize power output, improve fuel economy, and extend engine life. In addition, the ECM supports diagnostic features to simplify maintenance and prevent costly downtime.

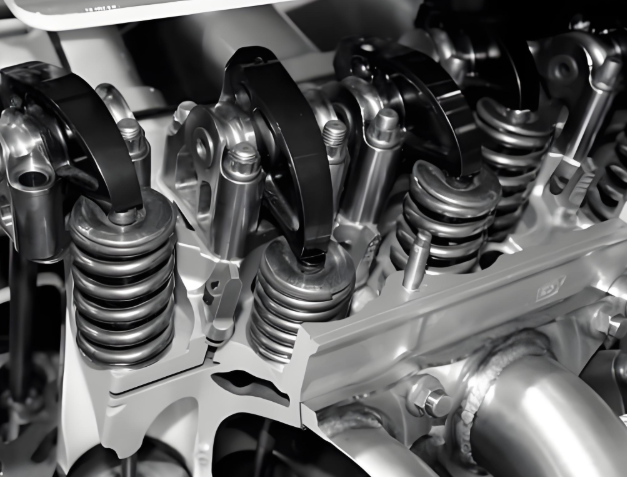

4. Robust Engine Block and Structural Design

Every Cummins industrial engine is built to withstand even the toughest operating conditions. The heavy-duty cast iron block, forged crankshaft, and strength-enhanced bearing are engineered for maximum toughness and power, providing long-term reliability even with continuous high-load application. Its ruggedness makes Cummins engines ideal for tough applications such as construction, mining, and material handling.

5. Overall Performance Advantage

Through the integration of these cutting-edge technologies, Cummins industrial engines deliver an absolutely balanced combination of power, efficiency, and durability. Advantages to customers are:

- Lower fuel and maintenance costs

- Longer service intervals

- Higher operating uptime

- Lower total cost of ownership (TCO)

Through innovation-led engineering, Cummins raises the performance bar on industrial engines, making it a trusted source of power for equipment makers and operators worldwide.

Part 3. Common Applications of Cummins Industrial Engines

Cummins industrial engines provide dependable power for small utility equipment to heavy-duty operation in numerous industries. Their dependability, flexibility, and high-performance characteristics are what have earned them the trust of clients in most adverse conditions worldwide.

1. Construction and Engineering Equipment

Cummins engines power a variety of heavy-duty equipment used in the construction industry, such as excavators, wheel loaders, bulldozers, motor graders, and rollers. The machines typically operate in dusty, high-load, and extended-hour conditions.

Cummins engines deliver consistent, assured torque output, better throttle response, and excellent reliability, delivering maximum productivity and minimal downtime on job sites. Its high fuel efficiency also allows contractors to reduce operating expenses as they adhere to strict emissions standards.

2. Farm Machines

Farm operations need engines that have fuel economy, power, and versatility. Cummins industrial engines are highly installed in tractors, combines, sprayer, and harvesters, delivering the torque and endurance needed for prolonged field operations.

With advanced electronic control and precise fuel injection systems, these engines enable farmers to provide better performance and less fuel consumption, even for longer planting or harvesting times.

3. Quarry and Mining Equipment

Minning conditions are among the most challenging in the world—extreme dust, vibration, and temperature changes. Cummins engines power haul trucks, drills, crushers, and loaders, with high power density and long-term reliability under heavy loads.

Heavy-duty engine design and high-performance cooling systems ensure dependable operation, allowing minning companies to achieve high production rates and lower maintenance expenses.

4. Power Generation Systems

Cummins is also a global leader in industrial generator sets and backup power solutions. Its engines are the first choice for continuous, prime, and standby power applications, ensuring reliable electricity supply in factories, data centers, hospitals, and construction sites.

The versatility of the fuel of the engines, rapid response to load changes, and low noise level make them ideal for stationary and mobile generator sets.

5. Marine Power Solutions

At high seas, the propulsion systems, auxiliary generator sets, and onboard equipment support of commercial, government, and recreational ships are powered by Cummins engines.

Built with a corrosion-resistant profile in a marine environment, they ensure smooth, efficient, and reliable performance over long voyages. With forceful torque delivery and effective cooling systems, Cummins marine engines ensure safe sailing and optimal fuel efficiency at sea.

Unsurpassed Performance Under All Conditions

Irrespective of whether they are operating under heat, cold, or altitude, Cummins Industrial Engines deliver consistent power, smooth operation, and exceptional durability.

Their long-established versatility and wide-reaching international service network allow customers to maintain their equipment running smoothly wherever the globe takes them, enhancing Cummins’ role as a trustworthy industrial power solution brand.

Part 4. Advantages of Using Cummins Industrial Engines

Choosing Cummins means choosing a durable and efficient power solution backed by global experience and record of performance.

1. Outstanding Reliability and Long Life

Cummins engines are tested thoroughly in the world’s toughest environments and are built with strong materials for long life and stability and maximum uptime. Their lifespan is far in excess of industry norms and makes them appropriate for continuous and heavy-duty use.

2. Excellent Fuel Efficiency

With high-pressure and high-combustion fuel injection technology, Cummins engines deliver maximum power at lower fuel consumption, with low long-term operating costs and minimal emissions.

3. Global Network Support

Global presence in over 190 countries across the world, Cummins provides global after-sales service with genuine parts supply and technical assistance to ensure your equipment runs smoothly anywhere in the world.

4. Compliance with the Environment

All of its engines are capable of meeting or surpassing EPA Tier 4 Final and EU Stage V standards. Cummins’ clean power technology allows customers to achieve both regulatory compliance and sustainability targets.

Cummins industrial engines, in every sense, combine power, efficiency, and reliability, and are the first choice for industries worldwide.

Part 5. Importance of Cummins Engine Parts and Maintenance

For industrial heavy-duty equipment, long-term and continuous performance is not only dependent on the engine but also on maintenance and the use of high-quality original parts. Cummins emphasizes that original parts and care are required to keep engines in smooth working condition and dependability throughout their entire service life.

1. Genuine Cummins Engine Parts

Cummins produces a complete range of OEM engine parts, including:

- Core components such as pistons, cylinder heads, crankshafts, and connecting rods

- Fuel and air parts such as injectors, filters, turbochargers, and cooling assemblies

- Electronic parts such as control modules (ECM) and sensors for efficient monitoring and optimization

Each genuine Cummins component is built, tested, and designed to the same exacting standards as the original engine, ensuring impeccable compatibility and maximum performance. Subpar or non-genuine components may result in increased wear, decreased efficiency, and system failure.

2. Scheduled Maintenance for Reliable Performance

Stringent adherence to the recommended Cummins maintenance interval is the best means of preventing costly downtime and extending engine life. This involves:

- Regular oil and filter maintenance to lubricate and reduce internal wear

- System checks of fuel and cooling systems to prevent overheating or contamination

- Cummins-certified service centers performing regular diagnostics and calibrations to detect issues early

- Periodic upkeep guarantees optimal fuel efficiency, smooth power, and reduced downtime, making industries operate cost-efficiently and economically.

3. Long-Term Benefits

Operators with the utilization of genuine Cummins parts in combination with professional maintenance are able to benefit from:

- Increased engine life

- Less frequent repairs and costs

- Increased equipment reliability and uptime

Really, maintaining a Cummins industrial engine in top shape with certified components and on-schedule service is more about maintenance and longevity, it’s about saving your investment and getting the maximum performance out of it for the long haul.

Part 6. How Longshine Supports Cummins Engine Users

Being a professional Cummins engine and parts supplier, Longshine seeks to provide sustainable, high-quality power solutions to customers worldwide. For equipment new installation, maintenance, or replacement, we offer one-stop services to help your machines run at their best.

Strengths of Longshine:

Large Inventory

We carry Cummins industrial engines and a huge collection of original replacement parts, covering a wide range of models for construction, mining, marine, and power generation applications.

Genuine Products

Longshine offers original Cummins parts with competitive price, which allows customers to achieve the optimal performance, quality, and cost-saving solutions.

Professional Technical Support

Our experienced personnel provides expert guidance on engine selection, installation, and maintenance to ensure that each product operates efficiently and safely in its particular application.

Fast and Effective International Shipping

With extensive experience in international export over many years, we ensure that each order, no matter if a single component or bulk consignment of components, arrives with you securely and on time, wherever you are.

At Longshine, we assist maintenance providers, equipment manufacturers, and end-users too, with customized Cummins engine and parts solutions to optimize equipment uptime and operational productivity.

Final Thoughts

Cummins Industrial Engines, with their superior performance, reliable quality, and strong global support network, have become an essential go-to in the industrial power segment. From construction to agriculture, and from mining to power generation, Cummins continues to forge ahead through innovation.

Also essential is having a trusted parts and engine supplier to offer effective long-term performance of your equipment. If you require high-quality Cummins engines and genuine Cummins parts, Longshine stands ready to provide steady and consistent power supply to your industrial operations.

FAQs on Cummins Engine

Are all Cummins 5.9 industrial engines interchangeable?

Not all Cummins 5.9 industrial engines are completely interchangeable. Differences in model years, emission requirements, configurations, and applications (construction, agriculture, or marine) result in some parts or entire engines being different. Always reference the individual engine model, serial number, and application requirements prior to replacement or swapping.

How many HP is an 8.3 Cummins?

The output of the 8.3 Cummins engine can vary within the range of horsepower (HP) rating from 210 to 360. Each engine will be built to specific applications with varying tuning within a particular range which designates the model. HP rating is further subjected to variation on-road, industrial, or marine applications. Engine listing will have all the necessary information related to the specific rating and application.

What are the different Cummins engines?

Various engines are designed and built for varying applications like the industrial, marine, off-highway, and on-road truck engines and for generator/backup power. Most common are the B Series (5.9L), C Series (8.3L), L Series (8.9L–15L), QSK Series (15L–95L), and the ISX/ISM Series truck engines which also carry an environmental emission and durability aside from power rating for each of the engines.