Are Parts Interchangeable On Different Gen Cummins? 12 Valve Vs. 24 Valve

Cummins, a globally renowned manufacturer of diesel engines, is widely recognized by users for its high reliability and durability. In the fields of trucks, pickup trucks and industrial machinery, Cummins engines have almost become synonymous with performance and long service life.

However, for car owners and maintenance personnel, an unavoidable question is: Can the parts of different generations of Cummins engines be interchanged? Are there any shared parts between the 12-valve and the 24-valve?

This issue may seem simple on the surface, but it actually involves upgrades in engine design, differences in part structures, and variations in technological development directions. Next, we will gradually sort out the overall generational differences and the compatibility of parts.

Differences Among Different Generations Of Cummins Engines

Before discussing part interchangeability, it is necessary to understand the development context of Cummins engines.

The first generation of Cummins (early version with 12 valves)

- Represented by the 5.9L inline six-cylinder diesel engine.

- The mechanical oil injection system is adopted, with a simple design and relatively low requirements for the processing accuracy of parts.

- It is renowned for its stability and ease of maintenance.

The second-generation Cummins (12-valve later stage to 24-valve initial stage)

- Some upgrades have been introduced on the basis of maintaining high durability.

- The 12-valve version still used mechanical fuel injection in the later stage, while the 24-valve version transitioned to electronic fuel injection.

- This is also the dividing line between 12-valve and 24-valve systems.

The third-generation Cummins (mainly 24-valve)

- The full adoption of electronic fuel injection technology has improved fuel efficiency and made emission control stricter.

- The structure is more complex, and the electronic control system becomes the core.

- The precision requirements for parts have been significantly raised.

From this evolution, it can be seen that different generations of Cummins have significant differences in fuel injection methods, valve designs, and electronic control systems, which directly affect the compatibility of parts.

Can Different Generations Cummins Parts Be Interchanged?

1. Interchangeable parts

Although there are generational differences, some parts can still be used across generations due to the same basic structure:

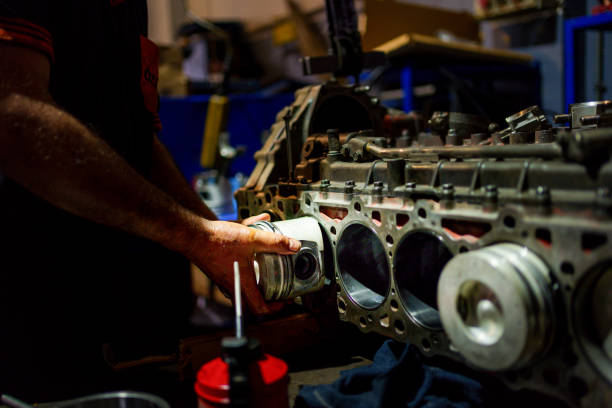

- Engine block: The main structure of the cylinder block varies limited among different generations, while the interfaces of some cylinder blocks and accessories remain consistent.

- Oil pumps and water pumps: These basic circulating components are designed similarly across multiple generations and can often be directly replaced.

- Filter element consumables: such as oil filters and fuel filters, generally have strong compatibility.

- Some sealing parts: Rubber sealing rings and gasket parts often have little difference and good universality.

2. Non-interchangeable parts

Most key components, due to design differences, cannot be used across generations:

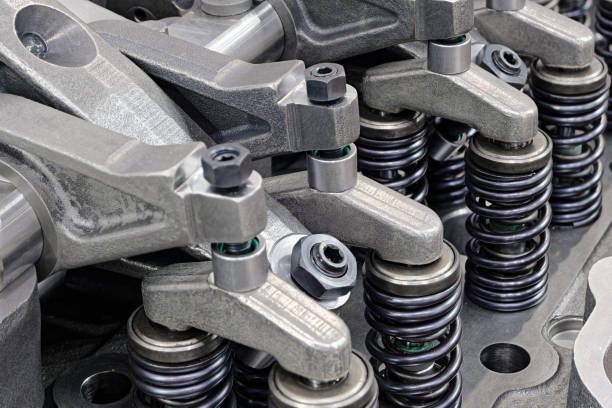

- Cylinder head and valve assembly: The number of valves for 12 valves and 24 valves is different, and the cylinder head designs are completely different, so they cannot be interchanged.

- Fuel injection systems: Mechanical fuel injection and electronic fuel injection have significant differences in structure and control methods, and related parts cannot be shared.

- Electronic control unit and sensors: The electronic fuel injection system relies on a large number of sensors and ECUs, which do not exist in the 12-valve system.

3. Situations where conditions are swapped

Some parts can be interchanged under special conditions, but usually additional modifications or adapter kits are required:

- Crankshaft and connecting rod: When the dimensions are close, they can be interchanged, but the tolerances need to be strictly calibrated.

- Intake and exhaust systems: Some exhaust manifolds or intake components are compatible after modification, but they are not directly interchangeable.

This reveals that although there are indeed a few interchangeable parts between 12-valve and 24-valve Cummins, the vast majority of key components are incompatible.

What Parts Can Be Shared Between 12-Valve And 24-Valve?

1. The sharing of internal components

- Shared parts: Cylinder block basic components, some gear transmission assemblies.

- Unshared parts: cylinder head, valves, fuel injectors, electronic control module.

When someone asks do 12 and 24 valve Cummins share internal parts? The answer is: Only the basic hardware is similar, and most of the internal components are not shared.

2. The sharing of external parts

- Shared parts: Filter elements, pump components, and some pulleys.

- Unshared parts: Intake manifold, exhaust system, and electronic control-related components.

For do 12 and 24 valve Cummins share parts? It can be clearly answered: Yes, but the quantity is limited, especially the key parts cannot be shared.

FAQ

1. Will the interchangeability of Cummins parts of different generations affect performance?

Yes. Even if some parts can be physically installed, there may be deviations in compatibility and performance, resulting in reduced power or shortened lifespan.

2. Which parts are most recommended for cross-generation use?

Filter element type, pump type, and some sealing parts. These parts have low risks and good compatibility.

3. What risks are there in using incompatible parts?

It may cause abnormal operation of the engine and even damage other related components. In the long term, the maintenance cost may be higher than the savings.

4. If it is necessary to switch generations, what should be done?

It is necessary to rely on modification kits or the guidance of professional technicians, and undergo strict testing after installation.

Suggestions For Selecting Parts

In actual operation, if you plan to replace Cummins engine parts, you can refer to the following principles:

- Confirm the engine model and production year: This is the first step in determining the compatibility of parts.

- Give priority to original factory parts: Original factory parts are more guaranteed in terms of compatibility and reliability.

- Be cautious when using counterfeit parts: If you choose counterfeit parts, select reputable brands and avoid low-quality products.

- Inter-generation replacement requires professional guidance: especially when it involves internal parts, it is best to have an assessment conducted by an authorized maintenance person from Cummins.

Final Words

The development of Cummins engines has undergone an evolution from 12 valves to 24 valves, and each upgrade has brought about changes in technology and structure.

Therefore, although parts of different generations of Cummins have a certain degree of interchangeability, they are not completely universal. Between 12 valves and 24 valves, only a few basic parts can be shared, while most key components require dedicated models.

For car owners, the safest approach is to select the corresponding parts based on the engine model. If intergenerational swapping is considered, thorough compatibility checks must be conducted and professional advice sought.