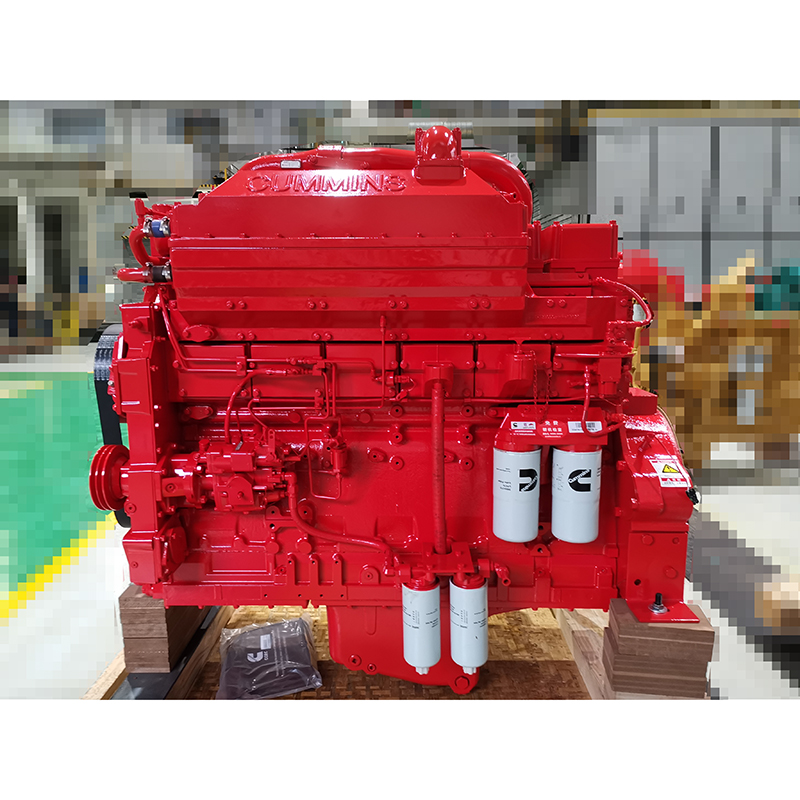

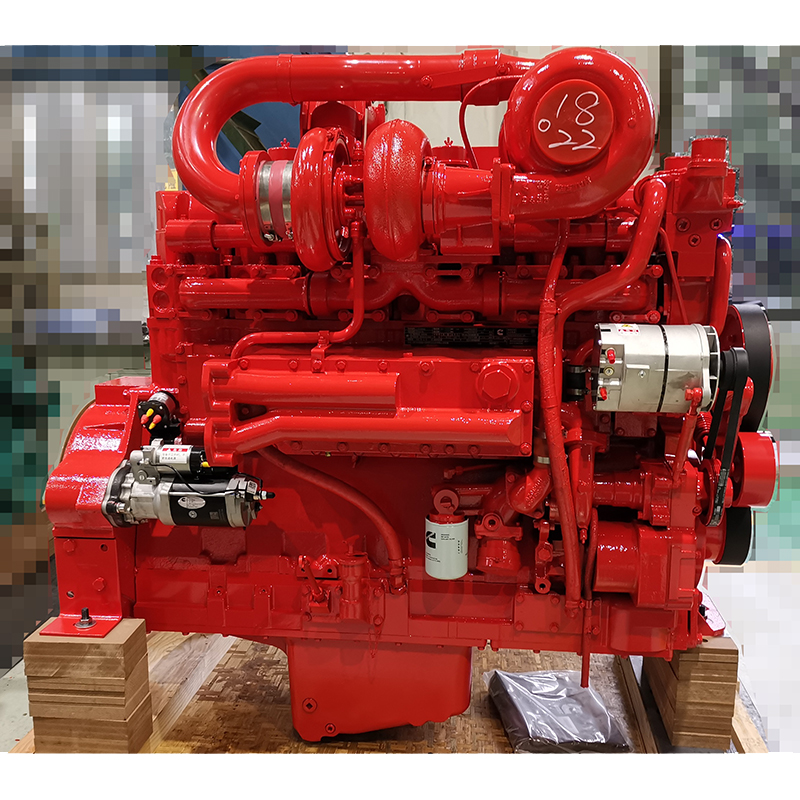

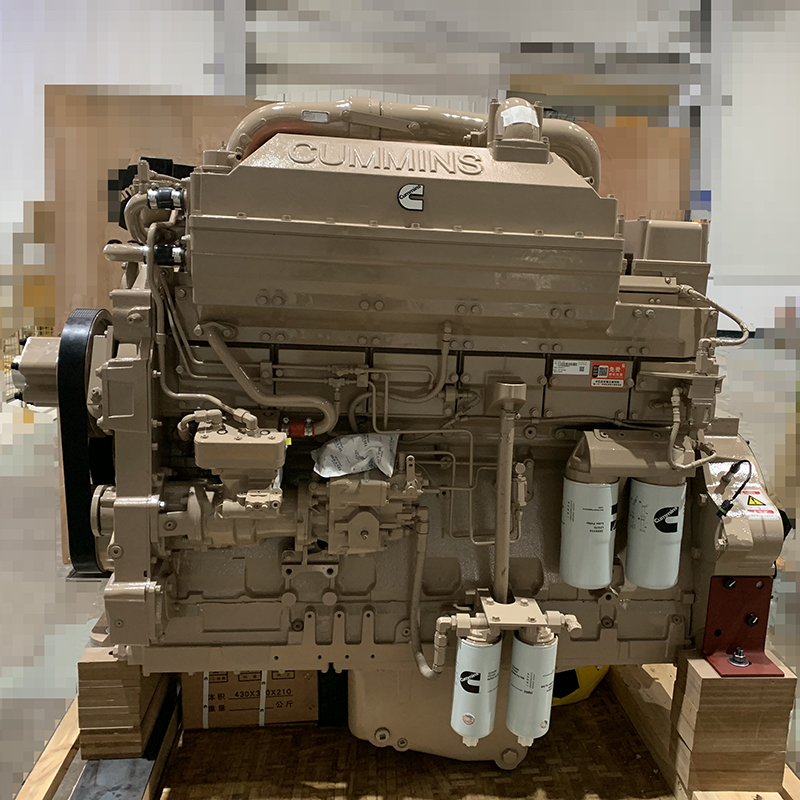

Product Description

Cummins Original Engine K19 KTAA19-C for Construction is a 19-liter turbocharged and aftercooled diesel engine designed specifically for heavy-duty construction machinery. With high torque output and reliable performance under continuous heavy loads, the KTAA19-C is ideal for demanding job sites. Engineered for durability and ease of maintenance, it ensures long service life in rugged construction environments.

Cummins KTTA19-C700 Technical Data Sheet

| Parameter | Specification |

| Engine Model | Cummins KTTA19-C700 |

| Type | 4-stroke, V12, twin-turbocharged aftercooled diesel engine |

| Displacement | 18.9 L |

| Bore × Stroke | 140 mm × 152 mm |

| Compression Ratio | 15.2:1 |

| Rated Power | 700 HP (522 kW) @ 2100 RPM |

| Peak Torque | 2500 N·m @ 1400-1600 RPM |

| Fuel System | PT Fuel system |

| Air intake method | Dual-Turbocharged & aftercooled |

| Cooling System | Water Cooling |

| Lubrication | Gear-driven forced lubrication (with centrifugal oil filter) |

| Oil Capacity | 50-55 L |

| Coolant Capacity | 65-70 L |

| Fuel Consumption | 195-205 g/kWh (at full load) |

| Emission Standard | Tier 2 off-road |

| Net Weight | 1900-2100 kg (depending on configuration) |

| Applications | Construction machinery, Mining equipment |

Cummins KTTA19-C Series Core Technical Comparison

| Parameter | KTTA19-C525 | KTTA19-C600 | KTTA19-C700 | KTTA19-C750 | KTTA19-C800 | KTTA19-C880 |

| Rated Power (HP / kW) | 525 / 392 | 600 / 447 | 700 / 522 | 750 / 559 | 800 / 597 | 880 / 656 |

| Rated Speed (RPM) | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Displacement (L) | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 |

| Cylinders / Layout | 6 Cyl / Inline + Twin Turbo | 6 Cyl / Inline + Twin Turbo | 6 Cyl / Inline + Twin Turbo | 6 Cyl / Inline + Twin Turbo | 6 Cyl / Inline + Twin Turbo | 6 Cyl / Inline + Twin Turbo |

| Bore × Stroke (mm) | 159 × 159 | 159 × 159 | 159 × 159 | 159 × 159 | 159 × 159 | 159 × 159 |

| Compression Ratio | 13.0:1 | 13.0:1 | 13.0:1 | 13.0:1 | 13.0:1 | 13.0:1 |

| Air intake method | Dual Turbocharged + Aftercooler | Dual Turbocharged + Aftercooler | Dual Turbocharged + Aftercooler | Dual Turbocharged + Aftercooler | Dual Turbocharged + Aftercooler | Dual Turbocharged + Aftercooler |

| Fuel System | PT Fuel system | PT Fuel system | PT Fuel system | PT Fuel system | PT Fuel system | PT Fuel system |

| Governor Type | Electronic or Mechanical | Electronic or Mechanical | Electronic or Mechanical | Electronic or Mechanical | Electronic or Mechanical | Electronic or Mechanical |

| Cooling System | Water-cooled (closed loop) | Water-cooled (closed loop) | Water-cooled (closed loop) | Water-cooled (closed loop) | Water-cooled (closed loop) | Water-cooled (closed loop) |

| Lube Oil Capacity (L) | 50–60 | 50–60 | 50–60 | 50–60 | 50–60 | 50–60 |

| Net Weight (kg) | 2100–2300 | 2100–2300 | 2100–2300 | 2100–2300 | 2300–2400 | 2400–2500 |

| Dimensions (mm) | ≈1700×950×1400 | ≈1700×950×1400 | ≈1700×950×1400 | ≈1700×950×1400 | ≈1800×1000×1450 | ≈1800×1000×1500 |

| Emission Level | Non-road / Tier 0 | Non-road / Tier 0 | Non-road / Tier 0 | Non-road / Tier 0 | Non-road / Tier 0 | Non-road / Tier 0 |

| Typical Applications | Construction machinery, Mining equipment | |||||

Features & Benefits

- Heavy-Duty Load Handling – Performs reliably under continuous low-speed, high-load conditions typical of construction sites.

- Rugged & Dust-Resistant – Engine components are designed to resist dust, debris, and vibration common in earthmoving operations.

- Service-Friendly Design – Simplified maintenance procedures and easy access to components reduce downtime on the job site.

- Fuel-Efficient Operation – Optimized for construction machinery to lower operating costs without sacrificing performance.

- High Torque Output – Provides powerful torque for pushing, digging, and lifting heavy loads efficiently.

Typical Applications

- Bulldozers and dozers

- Excavators and backhoes

- Wheel loaders and skid-steer loaders

- Concrete pump trucks and mixer trucks

- Mining and quarry machinery