Which Cummins Engine Models Use The Barrel And Plunger Fuel Injection System?

When understanding the performance and maintenance methods of a diesel engine, the fuel injection system is often an indispensable key link. Different fuel injection structures directly affect the reliability, applicable working conditions and later maintenance costs of the engine. Among them, the barrel And plunger fuel injection system has long been applied in many Cummins engines and has played an important role in the industrial and heavy-duty fields.

So, which Cummins engine models have adopted this fuel injection system? And why was it widely used for a long time? This article will elaborate on this issue.

What Is The Barrel And Plunger Fuel Injection System?

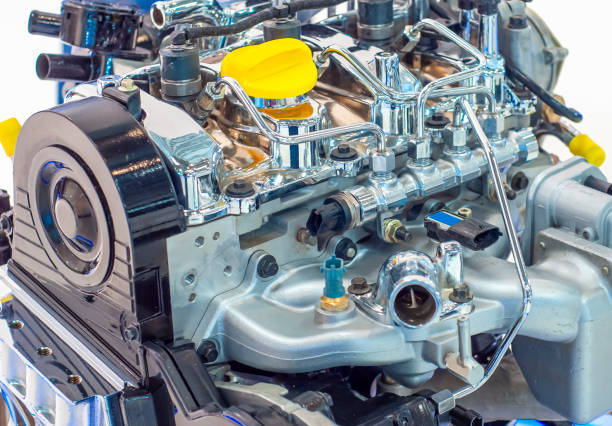

The barrel and plunger system, intuitively understood, can be regarded as a core structure that completes fuel metering and pressurization through mechanical movement. Among them, the Barrel (Plunger sleeve) is a precisely machined fixed component, while the Plunger (plunger) moves back and forth within it, delivering fuel to the injector through high pressure.

This structure does not rely on complex electronic control but ensures the stability of fuel injection through mechanical precision and fit clearance. It is precisely for this reason that it had strong practicality in early diesel engines, especially suitable for application scenarios with high requirements for stability and durability.

Which Cummins Engines Use The Barrel And Plunger System?

In Cummins product range, the barrel and plunger system mainly appeared on early mechanical fuel injection engines, especially concentrated in the fields of industrial power, construction machinery and generator sets.

1. Cummins N series engines

The N series engines represented by the N855 series are typical application objects of plunger fuel systems. This type of engine has a mature structure, a wide power range coverage, and is long-term used in heavy-load working conditions, with high requirements for the stability of the fuel system.

2. Some models of Cummins K series

In the K series engines with large displacement and high power output, some models also adopt the fuel injection structure with the plunger pair as the core. This design can maintain a relatively reliable fuel supply under high-load operating conditions.

3. An early version of Cummins L10 / M11

During the process of technological iteration, the early models of L10 And M11 still adopted the traditional mechanical fuel injection system, including the Barrel And Plunger structure. These models are in the transition stage from pure mechanical control to electronic control, so they retain a relatively classic design concept in the fuel system.

It should be noted that for the same engine model, the fuel system may vary in different years or configurations. The specific details still need to be confirmed in combination with the engine nameplate or the actual structure.

Why Do These Engines Choose The Barrel And Plunger Structure?

From the perspective of usage, the Barrel And Plunger system was not adopted widely by chance.

First of all, it has a relatively simple structure and high reliability. Under working conditions with a lot of dust, complex environments or limited maintenance conditions, mechanical fuel injection systems are often more likely to operate stably for a long time.

Secondly, this type of system has a relatively strong adaptability to fuel quality. In areas where fuel conditions are not ideal, the plunger structure can still maintain basic fuel injection functions, which is one of the reasons why it is common in industrial and export-oriented equipment.

Furthermore, from the perspective of maintenance, the plunger pair, as an independent component, is convenient for inspection and replacement, and is more operable for equipment that operates for a long time.

How to Determine Whether the Engine Uses the Barrel And Plunger System?

If it is necessary to confirm whether a certain Cummins engine adopts this fuel injection structure, the following aspects can be considered:

- Check the engine model and the year of manufacture to determine if it belongs to the early mechanical fuel injection series

- Identify the type of fuel injection pump that is matched with it, such as in-line pumps or early PT systems

- When repairing or replacing components of the fuel system, confirm through the structural form

All these methods can help users quickly check the type of fuel system to a certain extent.

Conclusion

The barrel and plunger fuel injection system, although gradually replaced by more advanced technologies in modern engines, still plays an indispensable role in many classic Cummins engines. Understanding which engine models adopt this structure not only helps in the correct selection of parts but also reduces unnecessary judgment costs during maintenance and use.

For these engines that are still in operation, being familiar with the characteristics of their fuel systems remains an important part of ensuring stable operation.