What’s the Difference Between Cummins Generator and Industrial Engine?

In the power systems market worldwide, Cummins is reliability, quality, and technological expertise. Whether an industrial engine or a generator set, Cummins is the preferred brand across industries because of its superior high-performance ability and unmatched durability.

But the majority of the users are wondering on maintenance or procurement: What’s the difference between Cummins generator and industrial engine? And how are they related?

Do not worry, today we will present a comprehensive overview of the differences, applications, and selecting the optimum power solution for your application.

Part 1. Familiarizing Ourselves with Cummins Power Systems

Being a global power solution leader, Cummins manufactures a wide range of products from engines, generator sets, filter systems, fuel systems, to control systems.

In the entire power system, the engine is the core, and the generator is the unit of energy conversion.

In short, an industrial engine is for delivering mechanical power, and a generator set is for converting the mechanical power into electrical power. We will describe them in detail in the following sections.

Part 2. What is a Cummins Generator?

A Cummins generator is a complete power generation setup that is well able to produce reliable electricity for varied applications. It consists of some primary components:

- Engine: Supplies the mechanical power needed to energize the generator.

- Alternator: Converts the mechanical energy of the engine into electrical power.

- Control System (Controller): Manages startup and shutdown, monitoring, and automatic protection, ensuring safe and efficient operation.

- Fuel and Cooling Systems: Provide long-term stable performance, prevent overheating, and ensure constant operation under heavy loads.

Applications

Cummins generators are used widely in:

- Mission-critical facilities such as hospitals, data centers, and telecommunications locations, where power is never permitted to be disconnected.

- On-site power generation for construction projects, mines, and oil fields.

- Standby power for industrial plants, commercial buildings, and marine vessels.

The primary advantages of Cummins generators are high degrees of integration, plug-and-play functionality, and smooth, continuous output, and the versatility of being able to use them as prime or stand-by power.

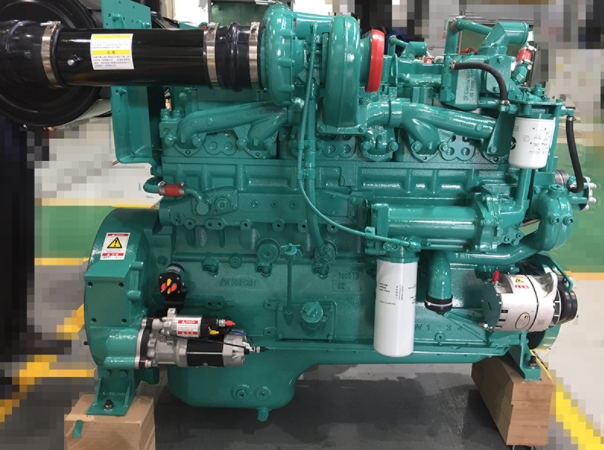

Part 3. What is a Cummins Industrial Engine?

A Cummins industrial engine is not an electrical power source per se, such as a generator, but is a mechanical power source, providing the torque and power that an industrial machine would require.

Cummins industrial engines are:

- Diesel Engines: World famous for reliability and fuel economy in heavy-duty applications.

- Natural Gas Engines: Green alternatives for businesses with environmental consideration.

- Mechanically and Electronically Controlled Engines: Delivering flexibility in performance, precision, and compatibility with sophisticated control systems.

Application Scenarios

Cummins industrial engines are used extensively in:

- Construction machinery, such as excavators, loaders, and bulldozers.

- Industrial equipment, such as air compressors, pumps, and other heavy machinery.

- Marine and agricultural gear, providing reliable propulsion and power.

- Fire pumps and rescue vehicles, where dependability is a top concern.

Cummins industrial engines provide high torque ratings, fuel efficiency, and durability in harsh environments, making them ideally suited for continuous heavy-duty operation and demanding industrial applications.

Part 4. Cummins Generators vs Industrial Engine: Key Differences

Cummins generators and industrial engines both share the same basic technology, high-performance, rugged engines, but they are designed to have different applications and are installed in different conditions. Below, we offer a detailed comparison on some of the most important aspects as well as generating a summary table to help you learn how they differ.

1. Function

Cummins Generator: The primary job is to convert the mechanical energy produced by the engine into stable, usable electrical power. It creates a constant supply of electricity for essential operations, industrial units, or emergency backup.

Cummins Industrial Engine: Acts as a mechanical power source, providing the necessary torque and rotational energy to run machinery, construction equipment, marine vessels, pumps, and other industrial appliances. It does not directly produce electricity.

2. Structure

Cummins Generator: Pre-packaged unit consisting of engine, alternator, controller, fuel system, and cooling system, which is immediately deployable and can operate dependably. The alternator generates electricity from engine power, and the controller handles startup, shutdown, monitoring, and protection.

Cummins Industrial Engine: A stand-alone engine system, designed to deliver only mechanical output. It can be customized to match specific equipment or operational requirements, and it may have either electronic or mechanical control systems depending on the application.

3. Output

Cummins Generator: Supplies electrical power, either AC or DC, and can be used to drive industrial plants, commercial plants, or backup systems.

Cummins Industrial Engine: Translates energy and torque into work to power machinery or equipment to accomplish such tasks as running compressors, pumps, or heavy construction equipment.

4. Typical Use

Cummins Generator: Delivers power supply in critical infrastructure (hospitals, data centers, telecommunications buildings), on-site or stand-alone power generation (construction projects, mines, oil fields), and auxiliary power for industrial plants or shipping applications.

Cummins Industrial Engine: Used to energize industrial equipment (air compressors, pumps), construction equipment (excavators, loaders, bulldozers), farm and marine machinery, and emergency equipment (fire-fighting pumps).

5. Installation

Cummins Generator: Delivered as an integrated assembly, pre-assembled for rapid installation and deployment. Its modular structure allows rapid connection with electrical systems without grand customization.

Cummins Industrial Engine: Needs to be installed in special equipment or machines. Its installation varies depending on the appliance it is powering, and it may need extra items such as gearboxes or drive shafts to efficiently transfer power.

6. Maintenance Emphasis

Cummins Generator: Repair entails both electrical parts (alternator, control panel, wiring) and mechanical parts (engine, fuel system, cooling system). Periodic inspections ensure efficient electricity supply as well as engine operation.

Cummins Industrial Engine: Maintenance is concerned with lubrication, fuel quality, and mechanical condition. Insuring sufficient torque output, preventing wear, and maintaining efficiency at prolonged heavy-duty usage ensures good long-term performance.

| Comparison Dimension | Cummins Generator | Cummins Industrial Engine |

| Function | Converts mechanical energy into electrical energy | Provides mechanical power to equipment |

| Structure | Engine + Alternator + Control System + Fuel/Cooling Systems | Standalone engine system |

| Output | Electricity | Torque and mechanical energy |

| Typical Use | Power supply, backup electricity | Driving industrial machinery or equipment |

| Installation | Integrated system for quick deployment | Can be customized and integrated into specific equipment |

| Maintenance Focus | Both electrical and mechanical systems | Fuel, lubrication, and mechanical performance |

Part 5. How to Choose Between a Cummins Generator and an Industrial Engine?

Choosing between a Cummins generator and an industrial engine is mostly dependent upon your power requirement and purpose of use. Your solution choice delivers efficiency, reliability, and optimal performance for your specific operational needs.

1. General Guidelines

Choose a Cummins Generator if your goal is to produce electricity, whether for continuous power supply, emergency backup, or remote site power. Generators are ideal for critical infrastructure, commercial facilities, or temporary power needs where stable electrical output is required.

Select a Cummins Industrial Engine if your application is to power mechanical devices, including pumps, compressors, construction equipment, or marine boats. Industrial engines provide high torque and mechanical energy directly to equipment without having to convert it into electricity.

2. Things to Consider

Power Requirements: Specify the output power needed and type of load your equipment or system will power. Check that the engine or generator can handle peak demand and continuous operation levels.

Operating Environment: Assess whether the system will operate in high-temperature, dusty, humid, or corrosive environments. Cummins engines and generators are designed to be rugged, but environmental conditions may influence the choice of model and protective features.

Fuel Type: Evaluate diesel, natural gas, or dual-fuel options based on availability, cost, and emission regulations within your location.

Maintenance and Support: Ensure that spare parts, technical support, and after-sales support are readily available for your solution that may minimize downtime and maintenance costs.

3. Practical Example

On a construction site, diverse power needs demonstrate the difference:

Lighting and temporary power at the site are generally given by a Cummins generator, providing reliable power to equipment, lighting, and office trailers.

Cummins industrial engines drive air compressors, pumps, or heavy equipment, providing direct mechanical power to power these equipment efficiently under continuous load.

By carefully evaluating your power requirements, environmental conditions, fuel supplies, and maintenance requirements, you can select the solution that best fits your operating needs, both for reliability and cost.

Summary

Though Cummins generators and industrial engines are known items, they are applied to different purposes and system configurations:

- Generator: Produces electrical power to drive systems.

- Industrial Engine: Produces mechanical power to drive equipment.

Understanding the differences between the two helps you make better decisions in project planning, equipment buying, and purchase of maintenance.

If you are looking for reliable Cummins engines or generators, and a trustworthy Cummins parts dealer, please feel free to contact Longshine to get professional help.