How to Optimize the Performance of Your Cummins PT Fuel System in Marine Applications?

When it comes to diesel engine performance, the fuel injection pump is one of the most critical components. A high-quality Cummins fuel injection pump ensures optimal fuel delivery, engine efficiency, and long-term reliability. While it might be tempting to opt for cheaper alternatives, investing in a genuine or premium aftermarket Cummins fuel injection pump can save you significant money over time.

Cummins PT (Pressure-Time) fuel systems are widely trusted marine diesel engines due to their reliability, fuel efficiency, and power delivery capabilities. To function optimally under marine environments, however, regular maintenance and optimization must take place; in this blog post, I aim to show how your Cummins PT fuel system can reach peak performance while mitigating issues and maintaining smooth performance for maximum engine operation.

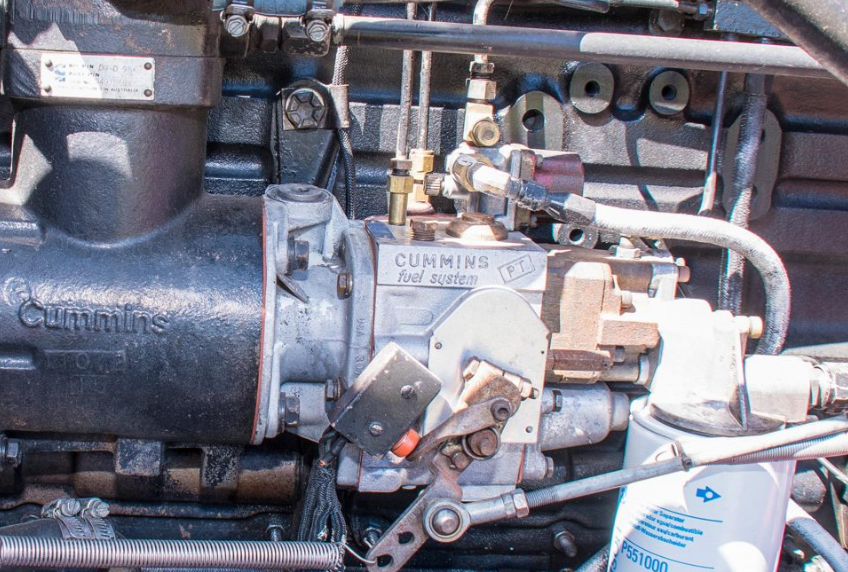

Cummins PT Fuel System Basics

The Cummins PT (Pressure-Time) fuel system is a mechanical fuel injection system designed for durability and precision in demanding applications, including marine engines. Unlike modern electronic systems, the PT system relies on hydraulic principles to regulate fuel delivery based on engine speed and load.

How It Works:

- A PT Fuel Pump: Driven by an engine’s gear train, this component generates proportional fuel pressure based on engine RPM.

- Injectors: Each injector meters fuel depending on both the pressure from the pump and how quickly the cylinders allow fuel into them.

- Governor: A governor regulates engine speed by controlling flow rates through the injectors.

- Fuel Lines and Filters: Ensure a clean fuel supply to avoid contamination of any kind.

This system is highly-regarded for its ease of operation, reliability, and low maintenance needs, making it perfect for marine environments requiring consistent performance. Thanks to fewer electronic components being exposed to saltwater or high humidity conditions than others. Proper care ensures optimal fuel efficiency, power output, and longevity in marine applications.

Common Performance Issues of Cummins PT Fuel System in Marine Engine

Cummins PT fuel systems are known for their durability and straightforward mechanical design; however, marine environments can present additional challenges that impact performance. Here are four major considerations when operating in marine environments.

1. Fuel Contamination by Water, Algae, and Debris)

Marine engines are particularly susceptible to fuel contamination from high humidity and water exposure. Water can lead to corrosion inside injectors and pumps while diesel algae and debris can clog filters and injectors, reducing combustion efficiency while power loss results from contamination; costly injector or pump failures are another concern associated with contamination, making regular testing, use of water separators, and tank maintenance essential to avoid this issue.

2. Injector Wear and Malfunction

Over time, injector components may wear down, especially in harsh saltwater environments. Worn injectors result in poor atomization, leading to incomplete combustion, reduced engine power, increased fuel consumption, higher emissions, and even possible engine knocking or misfires if left lingering too long before replacement is performed. Regular inspection and replacement help ensure optimal performance is always met.

3. Pressure Loss or Fluctuations in the Fuel Line

The PT system depends on consistent fuel pressure to deliver the right amount of fuel at the correct time. Pressure fluctuations—caused by air leaks, worn pump components, or clogged filters—can lead to rough idling, hesitation during acceleration, or stalling. Diagnosing and correcting pressure issues often involves checking for loose fittings, damaged hoses, and ensuring the pump and fuel control valve are functioning properly.

4. Improper Pump Calibration or Timing

If the injector pump is not properly calibrated or becomes misaligned, it can lead to incorrect fuel delivery. This causes poor engine response, uneven power output, excessive smoke, and increased fuel consumption. Timing issues often arise after component replacements or maintenance and require precise recalibration using manufacturer specifications. Regular verification and adjustments ensure peak engine efficiency and performance.

Best Practices for Optimizing PT Fuel System Performance for Marine Applications

To ensure your Cummins PT fuel system delivers peak performance and long-term reliability in demanding marine environments, implementing the following best practices is essential:

1. Implement a Routine Maintenance Schedule

Regular preventive maintenance is the foundation of optimal PT fuel system performance. This includes scheduled inspections of fuel lines, filters, injectors, and the injector pump. Replace filters before they become clogged and clean components prone to buildup. Periodic servicing helps detect early signs of wear or contamination, preventing major failures and expensive repairs down the line.

2. Always Use Clean and High-Quality Marine-Grade Fuel

Fuel quality has an immense effect on combustion efficiency and injector life span, so always choose high-quality marine-grade diesel with proper sulfur levels and marine engine-specific additives for use. Keep fuel stored in clean tanks using biocides or stabilizers to inhibit microbial growth or sludge formation; invest in fuel filtration systems capable of water separation to protect PT systems further.

3. Regularly Inspect and Adjust the Injector Pump and Timing

The performance of your PT fuel system depends heavily on precise injection timing and pressure, especially after engine work has taken place. Be sure to calibrate the injector pump according to Cummins specifications after any major engine work, then check its timing periodically or upon any signs of rough running or increased fuel consumption for best performance. Properly adjusted pumps are key in providing consistent engine output, economy fuel usage, and reduced emissions levels.

4. Monitor and Maintain Engine Cooling System

Overheating can wreak havoc with a marine engine’s fuel systems by degrading lubricants and increasing wear-and-tear on components, so ensuring its cooling system functions without blockages, leaks, or worn parts is of key importance in prolonging the service life of both injector pumps and fuel components. A stable operating temperature ensures injector pumps run within their specified tolerance,s thus prolonging their service lives over time.

5. Inspect for Air Leaks and Fuel Line Integrity

Air entering the fuel system can disrupt fuel pressure and delivery, causing misfires, power loss, or starting issues. Regularly inspect all fuel lines, connectors, and seals for signs of wear, corrosion, or looseness. Replace damaged hoses and ensure all fittings are tightened to spec. Maintaining a sealed, pressurized fuel system is crucial for consistent performance.

More Upgrades and Enhancements for Better Performance

If you’re looking to push your Cummins PT fuel system beyond stock capabilities in marine applications, consider these three high-impact upgrades:

1. Cummins OEM Performance Upgrade Kits

Cummins offers factory-engineered upgrade kits designed specifically for PT systems that include higher-tolerance plungers, hardened cam followers, and precision-ground delivery valve assemblies designed to withstand saltwater corrosion while providing more consistent fuel pressure under load. These components help increase operational uptime.

- Increased Durability: Hardened materials resist wear from high crankshaft speeds and vibration, offering increased longevity.

- Enhance Consistency: Tighter manufacturing tolerances help ensure consistent shot-to-shot variation for smoother throttle response.

- Plug-and-Play Installation: Our kits contain all of the gaskets and seals necessary for an effortless plug-and-play installation process, reducing downtime while guaranteeing compatibility with existing pumps.

2. Electronic Fuel Control Conversion Kits

While PT systems are entirely mechanical, aftermarket electronic conversion kits add an electronic link between an engine’s ECU and injector pump. By adding an electric actuator on your fuel rack and connecting to the engine management system software, you gain a number of benefits:

- Real-Time Monitoring: Instant feedback on rail pressure, rack position, and fuel delivery events.

- Adaptive Mapping: The ECU can adapt fuel delivery on-the-fly for different loads, sea states, or fuel qualities — optimizing economy and power.

- Diagnostic Capabilities: Error codes and recorded events provide useful diagnostic capabilities that help pinpoint issues before they lead to systemic failures.

3. High-Precision Performance Injectors and Nozzles

Upgrading to performance-grade injectors equipped with stainless-steel bodies and multi-hole nozzle tips can dramatically enhance atomization and spray pattern, which are essential elements for efficient combustion in marine engines. Key benefits may include:

- Finer Atomization: Smaller droplets burn more completely, reducing soot and unburned hydrocarbons.

- Optimized Spray Pattern: Precise hole geometry ensures an even fuel cloud, improving power output and throttle response.

- Corrosion Resistance: Marine-grade materials provide corrosion protection from salt air corrosion and fuel contaminants, thus prolonging service intervals and prolonging their service lives.

These upgrades, combined with careful maintenance,e will bring increased reliability, improved fuel economy, and enhanced responsive performance from your Cummins PT fuel system at sea.

Where to Find Original Cummins PT Fuel System?

When looking to maintain or upgrade your Cummins PT fuel system, it’s crucial to source parts from an authorized and reliable supplier to ensure quality, reliability, and compatibility with your marine engine. One trusted name for original Cummins PT fuel system components is Longshine, a reputable supplier of genuine Cummins parts.

Longshine offers a comprehensive range of original Cummins PT fuel system parts, including injectors, pumps, nozzles, and fuel control components. Their products are sourced directly from Cummins, ensuring that you receive authentic, high-performance components built to the manufacturer’s exacting standards. With Longshine, you can expect expert customer service, competitive pricing, and fast delivery, helping you keep your marine engine running at its best.

Visit Longshine for your original Cummins PT fuel system parts and upgrade your marine engine performance today.