How Does a Cummins QSB Work?

Many people have heard of the reputation of Cummins QSB engines: strong power, low fuel consumption and good durability. However, in the actual usage process, such a problem is often encountered – why does the fuel consumption of the equipment vary under the same working conditions? Why do I sometimes feel lacking in motivation? Why did the emission indicators suddenly fail to meet the standards?

The answers to all these confusions all revolve around one core question: How does an engine work? If one only knows that it is “easy to use” but does not understand its working principle, it will be very difficult to judge problems at critical moments, let alone maintain it scientifically.

Therefore, understanding the working logic of QSB can not only help us understand why it performs well, but also enable us to quickly find the right direction when problems arise.

The Design Positioning And Advantages Of Cummins QSB

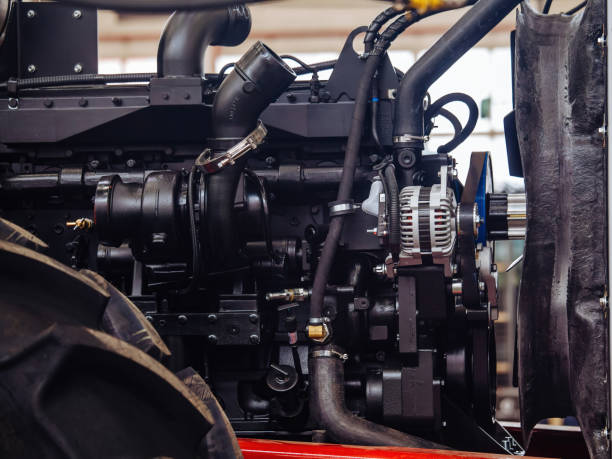

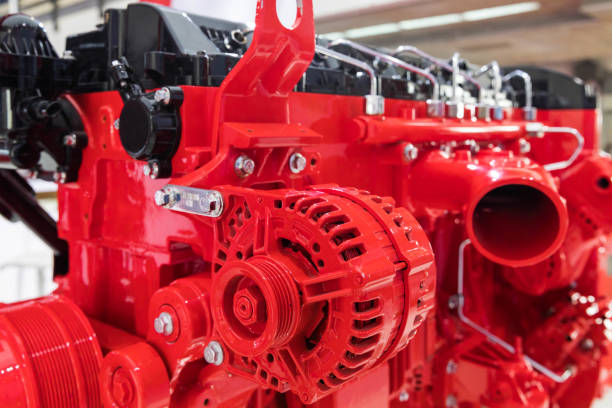

The Cummins QSB series is a type of in-line four-cylinder or six-cylinder diesel engine, widely used in construction machinery, marine power and generator sets. Compared with traditional diesel engines, it has three significant advantages:

- Efficient combustion: Less fuel, more energy released

- Intelligent electronic control: The system can automatically adjust according to different environments and working conditions, ensuring stable power all the time

- Modular structure: Maintenance and parts replacement are more convenient, reducing downtime and maintenance costs

In other words, Cummins QSB is not only powerful, but also takes into account performance, economy and durability in its design. This is also an important reason why it is widely adopted in many fields.

The Working Principle Of Cummins QSB

1. Intake and pressurization

For complete combustion, there must first be sufficient air. The QSB is equipped with a turbocharger in the intake stage, which can compress the outside air and send it into the cylinder. Compressed air has a higher density and a greater oxygen content, providing sufficient conditions for the subsequent combustion process.

This is also the key reason why QSB can still maintain abundant power under high-load conditions.

After the air is ready, how the fuel enters the cylinder is of vital importance. QSB adopts a high-pressure common rail injection system, which is a more advanced method than traditional mechanical fuel injection. It can atomize fuel and spray it into the cylinder at extremely high pressure in an extremely short time. The fuel distribution is more even and the combustion is more complete, thereby reducing fuel consumption as well as black smoke and harmful emissions.

The accuracy of injection is also an important factor affecting the smoothness of the engine. It is precisely through this precise control that QSB enables the engine to remain stable under various operating conditions.

3. Combustion and Energy Release

When compressed air is thoroughly mixed with atomized fuel and ignited, high temperature and high pressure are instantly generated, pushing the piston down and driving the crankshaft to rotate, ultimately converting into mechanical power. This process is constantly repeated, and the engine can continuously output energy.

Whether combustion is complete or not not only determines the strength of power, but also directly affects fuel consumption and emission levels.

4. Exhaust gas and tail gas treatment

The exhaust gas after combustion is discharged through the exhaust system, but before leaving the engine, it still needs to go through the exhaust gas recirculation (EGR) and exhaust gas treatment device. The former can lower the combustion temperature and reduce the emission of nitrogen oxides. The latter ensures that the exhaust gas complies with environmental protection regulations.

It is precisely these aspects that make QSB not only powerful but also environmentally friendly.

5. Electronic Control Unit (ECU) – The brain of the Engine

The precise control of the entire process cannot be achieved without the adjustment of the ECU. It will receive real-time data feedback from sensors, such as intake pressure, fuel injection volume, temperature, etc., and quickly make adjustments. Whether it is a cold start, long-term high-load operation, or sudden load changes, the ECU can ensure that the engine operates in the best condition.

How To Keep Cummins QSB In Best Condition All The Time?

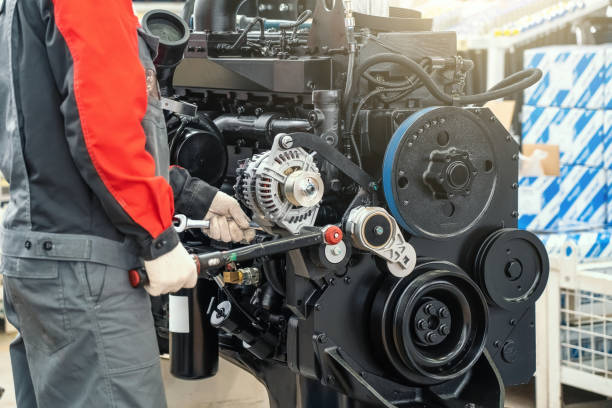

The lifespan and performance of an engine depend not only on its design but also on the way it is used and maintained on a daily basis. Although QSB is sturdy and durable, if it is neglected for maintenance, it may still experience performance degradation or malfunction prematurely. To keep it in the best condition all the time, you can start from the following aspects:

Adhere to basic maintenance

Engine oil and filters are the blood and filter screen of an engine. Replacement at regular intervals can prevent impurity deposition and insufficient lubrication, fundamentally reducing wear.

Pay attention to the purity of air and fuel

Once the intake system and fuel system are contaminated, the combustion efficiency will drop significantly, and an increase in fuel consumption is inevitable. Keeping the air filter and fuel clean is a prerequisite for ensuring the efficient operation of the engine.

Regularly inspect key systems

The turbocharger and fuel injection system are the core components of QSB. By regularly checking for leaks, blockages or wear, sudden drops in power or abnormal fuel consumption can be avoided.

Use original factory parts reasonably

All the components of the engine are designed through matching. Using original factory accessories not only ensures stable performance but also avoids hidden wear and tear caused by compatibility issues.

Utilize the data from the electronic control system

The ECU can record the operational status and abnormal information in real time. If data can be read regularly, not only can potential hazards be detected in advance, but it can also help technicians quickly locate problems, thereby reducing unnecessary downtime.

Through these measures, QSB can not only extend its service life, but also maintain stable power output and lower usage costs during long-term operation.

Common Problems And Cause Analysis

Even though QSB has an advanced design and stable performance, some common problems may still be encountered during use. Understanding the principle behind it often enables one to find the cause more quickly:

Insufficient power

When you feel that the engine output is weakening, one of the common reasons is that there is a problem with the intake or turbocharging system. Insufficient air volume will directly affect the combustion efficiency, thereby leading to a decrease in power.

Increased fuel consumption

If fuel consumption suddenly increases, it is often related to the fuel injection system. Wear of fuel injectors or abnormal fuel pressure can both lead to poor atomization of fuel, incomplete combustion, and naturally consume more fuel.

Black smoke is coming out of the exhaust

Black smoke is usually a sign of incomplete combustion. Apart from fuel injection issues, clogging of the air filter or obstruction of the intake passage can also lead to this situation.

Emissions do not meet standards

When the exhaust gas indicators suddenly become abnormal, the cause may be that the EGR valve is stuck or the post-treatment device is blocked, which will prevent the exhaust gas from circulating and purifying normally.

Final Thoughts

The working logic of Cummins QSB can be simply summarized as: intake → fuel injection → combustion → exhaust → electronic control regulation.

These five links are interlinked, forming an efficient and stable dynamic cycle. It is precisely because of such a design that QSB can ensure power while taking into account fuel consumption, environmental protection and durability.

When you truly understand its operation mode, you will no longer feel at a loss when encountering problems or conducting maintenance. Instead, you will be able to make more confident judgments and ensure that this engine is truly put to the best use.