What are 6.7 Cummins Engine Problems and How to Fix?

6.7L Cummins engine is very popular in heavy-duty pickup trucks and commercial vehicles such as the Dodge Ram 2500/3500. It is highly renowned for its robust performance and excellent towing ability. However, as much as it has excellent capabilities, it is not issue-free. The majority of owners encounter recurrent mechanical or electronic issues with long-term use.

Here, we will provide you with a comprehensive overview of 6.7 Cummins engine problems. More importantly, how to fix them. Our goal is to help you know this engine inside and out and not let minor issues turn into major repairs. Let’s begin!

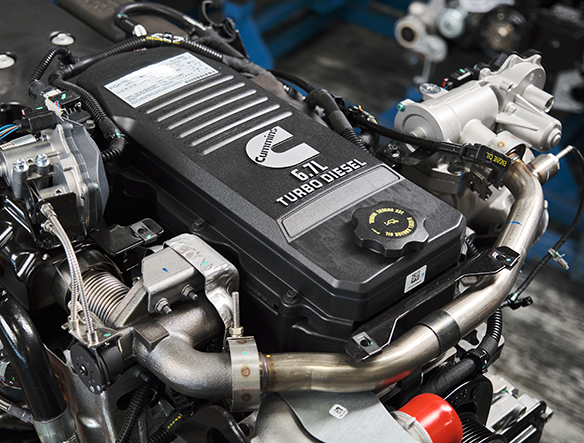

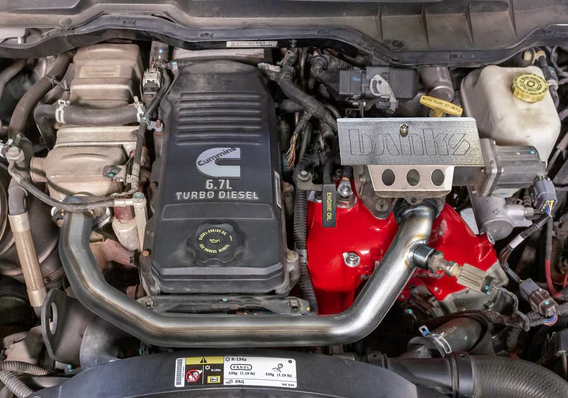

Part 1. Introduction to the 6.7L Cummins Engine

6.7L Cummins engine, released in May 2007 as a successor to the 5.9L version, is an inline six-cylinder turbocharged diesel engine known for its durability and strong performance. Designed to meet stricter emissions regulations, it incorporates advanced technologies such as Exhaust Gas Recirculation (EGR), Diesel Particulate Filter (DPF), and Selective Catalytic Reduction (SCR) systems to reduce harmful pollutants.

This engine is widely used in heavy-duty applications including:

- Dodge/RAM 2500 and 3500 series heavy-duty pickup trucks

- Commercial hauling trucks and construction vehicles

- Agricultural machinery and mining equipment requiring robust power and reliability

Power, efficiency and compliance with environmental regulations have contributed to its widespread usage in hardworking environments.

Part 2. 6.7 Cummins Engine Problems and Their Solutions

Here, we present 14 common issues of the 6.7L Cummins engine along with symptoms, causes, and recommended solutions.

1. EGR Valve and Cooler Issues

Symptoms:

- Unstable idle, engine may stall

- Black smoke from exhaust, increased emissions

- Reduced fuel efficiency and higher fuel consumption

- Check Engine light illuminated on the dashboard

Causes: The Exhaust Gas Recirculation (EGR) system reduces nitrogen oxide emissions by recirculating cooled exhaust gases back into the intake. However, carbon deposits accumulate over time in diesel engines, causing clogging or leaks in the EGR valve and cooler, which affects airflow and combustion efficiency.

Solutions:

- Regularly remove and clean the EGR valve and cooler to remove carbon buildup

- Replace damaged components promptly to prevent further damage

- In some regions, “EGR delete” modifications are used to remove the system entirely, but compliance with local regulations is essential

2. Turbocharger Failures

Symptoms:

- Noticeable loss of engine power and sluggish acceleration

- Whining, whistling, or stuttering noises from the turbocharger area

- Oil leaks near the turbo seals

Causes: Turbocharger bearings rely on engine oil to provide them with proper lubrication and cooling, so poor quality or insufficient supply accelerates wear on bearings, while carbon buildup can clog Variable Geometry Turbo (VGT) mechanisms resulting in malfunction.

Solutions:

- Use high-quality engine oil and maintain proper oil levels

- Allow the engine to idle after long drives to cool the turbocharger

- Replace the entire turbocharger assembly if severely damaged

3. Diesel Particulate Filter (DPF) Clogging and Frequent Regeneration

Symptoms:

- Frequent DPF regeneration cycles causing performance dips

- Increased fuel consumption

- Sluggish throttle response

Causes: The DPF traps soot particles to reduce emissions. Short trips or prolonged low-speed driving prevent the exhaust from reaching temperatures high enough to burn off soot, causing clogging.

Solutions:

- Avoid frequent short trips; maintain highway speeds periodically to aid self-cleaning

- Perform forced regeneration using diagnostic tools as needed

- Clean or replace the DPF when necessary

- DPF removal may be an option where legal, but it carries regulatory risks

4. Injector Damage

Symptoms:

- Difficulty starting, especially during cold starts

- Rough or unstable idle

- White smoke or unusual exhaust odors

Causes: The high-pressure common rail system requires precise injectors. Contaminated fuel or water intrusion damages injector nozzles, leading to poor spray patterns and combustion issues.

Solutions:

- Use high-quality diesel fuel and filters

- Periodically inspect and service injectors every 80,000–100,000 km

- Ensure fuel system is free from water and contaminants

5. Head Gasket Failure

Symptoms:

- Engine overheating

- Coolant mixing with engine oil, causing milky oil appearance

- Radiator pressure anomalies and possible coolant leaks

Causes: A damaged or blown head gasket or warped cylinder head causes poor sealing between coolant and oil passages, leading to leaks.

Solutions:

- Replace with OEM or high-quality head gaskets

- Inspect and machine cylinder head if warped or damaged

- Upgraded head bolts (e.g., ARP) may be used for enhanced sealing in modified engines

6. Fuel Pump Problems

Symptoms:

- Difficulty starting the engine

- Reduced power output

- Engine stalling intermittently

Causes: Fuel pump wear or electrical faults in the pump or control system cause insufficient fuel pressure or interruptions in supply.

Solutions:

- Diagnose fuel pump pressure and electrical systems using proper tools

- Replace faulty fuel pumps or repair control units as necessary

7. Oil Pump and Lubrication Issues

Symptoms:

- Abnormal oil pressure readings; oil warning light on

- Increased engine noise, such as knocking or rattling

- Excessive oil consumption or degraded oil quality

Causes: Worn oil pump, clogged oil passages, or low oil levels cause inadequate lubrication of engine components.

Solutions:

- Regular oil and filter changes per manufacturer recommendations

- Clean oil passages if clogged

- Replace oil pump if wear or failure is detected

8. Intake Manifold and Boost Leak Problems

Symptoms:

- Decreased engine power and sluggish acceleration

- Rough or unstable idle

Causes: Stuck or malfunctioning boost pressure relief valve and leaks in intake manifold seals cause improper boost pressure regulation and air leaks.

Solutions:

- Repair or replace the boost pressure relief valve

- Inspect and reseal intake manifold or replace worn seals

9. Water Pump Failure

Symptoms:

- Engine overheating; high coolant temperature gauge readings

- Coolant leaks or visible fluid around the water pump

Causes: Worn bearings or failed seals in the water pump cause coolant circulation issues and leakage.

Solutions:

- Replace faulty water pump promptly

- Check cooling system for leaks and proper pressure

10. Intake System Leaks

Symptoms:

- Lack of power during acceleration

- Unusual noises in the intake system, especially under load

Causes: Cracked or damaged intake hoses, loose fittings, or worn seals cause air leaks, leading to improper air-fuel mixture.

Solutions:

- Thoroughly inspect intake hoses and connections

- Replace damaged hoses and worn seals to ensure airtight system

11. ECU and Sensor Failures

Symptoms:

- Persistent Check Engine light

- Difficulty starting or abnormal engine operation

- Loss of power or rough running

Causes: Software issues in the Engine Control Unit (ECU) or failure of critical sensors (e.g., intake air temperature, pressure sensors) impair engine management.

Solutions:

- Use diagnostic scanners to read fault codes and update ECU software

- Repair wiring or replace faulty sensors as needed

12. Crankshaft Position Sensor Failure

Symptoms:

- Engine fails to start

- Engine stalls intermittently during operation

Causes: Damaged or faulty crankshaft position sensor causes incorrect or missing signal to the ECU, disrupting ignition and fuel injection timing.

Solutions:

Inspect and replace faulty crankshaft position sensor

13. Exhaust System Leaks or Blockages

Symptoms:

- Loud or unusual exhaust noises

- Reduced engine power and increased fuel consumption

- Abnormal emissions failing inspection

Causes: Cracked exhaust pipes, loose flanges, soot buildup, or failed valves restrict exhaust flow.

Solutions:

- Inspect and repair or replace damaged exhaust components

- Clean soot deposits regularly to maintain flow

14. Engine Belt and Tensioner Failures

Symptoms:

- Squealing or rubbing noises from the engine bay

- Malfunction of accessories like alternator or air conditioning compressor

Solutions:

- Regularly inspect belts for wear and proper tension

- Replace worn belts and faulty tensioners to ensure accessory drive reliability

Part 3. Differences in Common Issues Across Model Years

Since its debut in 2007, the 6.7L Cummins diesel engine has gone through many changes, evolving into each successive generation while adding its own problems, particularly regarding emissions control and electronic control systems. Being aware of which problems arise at specific production times helps owners and shop technicians better diagnose and service these engines.

Below is a summary of the most frequent issues by model year range:

2007.5 – 2012 Models

Common Issues: Clogging of EGR valve due to carbon build-up, DPF issues and early Variable Geometry Turbocharger (VGT) models which stick or fail are some of the more frequently reported issues.

Details: The initial generation had difficulty meeting emissions standards and would require frequent servicing for EGR and DPF systems. VGT turbos in particular suffered reliability issues which often led to power loss or excessive noise production.

2013 – 2018 Models

Common Issues: Failure of sensors in an electronic control system, issues with Selective Catalytic Reduction (SCR), DEF injector and dosing issues.

Details: As emissions standards tightened, more sophisticated electronic controls were utilized. While this increased performance and emissions control, additional complexity emerged; sensors and SCR components occasionally failing, leading to warning lights and driving difficulties.

2019 to Present Models

Common Issues: Overall system upgrades have improved reliability; however, SCR system maintenance and Engine Control Module (ECM) upgrades remain key concerns.

Details: Modern engines feature refined hardware and software, reducing many previous faults. Still, ongoing attention to SCR system health and timely ECM updates is essential to maintain compliance and optimal engine function.

Summary Table: Common Issues by Model Year

| Model Year Range | Common Problems | Key Notes |

| 2007.5 – 2012 | EGR clogging, DPF issues, VGT sticking | Early emission controls required frequent upkeep; first-gen VGT less reliable |

| 2013 – 2018 | Sensor failures, SCR system problems | More electronics introduced; sensor and DEF system faults common |

| 2019 – Present | SCR maintenance, ECM updates | Improved reliability; continued attention needed on SCR and software updates |

Part 4. Preventive Measures and Maintenance Tips

Maintenance is key to maintaining long-term performance, efficiency and reliability for any engine – the 6.7L Cummins is no exception – its sophisticated emissions and control systems do not tolerate neglect as easily. By following best practices listed herein most problems associated with it can be prevented:

1. Focus on High-Quality Fuel and Engine Oil

The quality of diesel fuel matters, only buy Cummins parts from reliable stations to reduce injector and pump failure risk and fill your tank only when necessary.

Select an API CJ-4, CK-4 or FA-4 engine oil to provide maximum protection, especially at high loads or temperatures.

Why quality oil matters: Quality oil provides sufficient lubrication to critical components like the turbocharger, crankshaft and camshaft to prevent premature wear and overheating of parts like the turbocharger, crankshaft and camshaft.

Change Intervals: Follow manufacturer specifications; however, for towing, off-road use or harsh climate environments it may be prudent to shorten this interval (i.e. every 5,000-8K miles / 8-13,000 Km).

2. Periodically Replace Oil and Fuel Filters

Oil filters: Catch nasty particulates that would otherwise ruin engine internals. Replace during every oil change.

Fuel filters: Diesel engines are susceptible to contamination and water; clogged filters can lead to injector failure or fuel starvation.

Recommendation: Replace fuel filters at every 15,000–20,000 miles (24,000–32,000 km), or as per your vehicle’s manual.

3. Avoid Frequent Short Trips

Why it matters: Frequent short trips prevent the engine from reaching optimal operating temperature. This affects the DPF system, as regeneration cycles require higher exhaust temperatures to process.

Best practice: Take your truck onto the highway every month for 30–45 minutes of medium to high-speed driving to allow the DPF to completely regenerate.

4. Fit a Turbo Cool-Down Timer

What it does: A turbo timer allows the engine to idle when ignition is turned off, with oil still pumping through the turbo while it cools down.

Why it is useful: Prevents oil coking and heat degradation of the turbocharger bearings and seals, significantly increasing turbocharger life.

Alternative method: If you don’t own a timer, idle manually for 1–3 minutes after heavy towing or high-speed driving.

5. Periodically Read and Watch Trouble Codes

Use an OBD-II scanner: Modern engines store valuable information and trouble codes prior to the Check Engine Light illumination.

Periodic scans help you:

- Detect early issues (e.g., sensor failure, loss of fuel pressure)

- Perform scheduled maintenance instead of repair

- Avoid catastrophic failure by fixing minor problems in a timely manner

Tool recommendation: Basic Bluetooth OBD-II scanners and software like Torque, AlphaOBD, or FORScan are inexpensive and adequate.

Additional Tips

Prior to heavy engine use in cold conditions, always warm it up beforehand and check coolant and oil levels to prevent overheating and loss of lubrication. Check clamps, hoses and belts regularly for leakage or wear during servicing appointments.

By following these maintenance routines, you can easily extend the longevity of your 6.7L Cummins engine while simultaneously cutting repair costs and reaching peak performance under demanding conditions.

Part 5. Is the 6.7L Cummins Still Worth Buying?

One of the most renowned diesel engines for light and heavy-duty trucking applications, the 6.7L Cummins has earned itself an excellent reputation in power as well as durability. But with changing emissions laws and technologies emerging since its debut, potential buyers may now question if purchasing it would still make financial sense today?

Here’s now an overview of its advantages and disadvantages.

Advantages:

High Torque Output: The 6.7 Cummins offers stout low-end torque, which suits it well for heavy hauling, towing large trailers, or providing room for tough off-road driving.

Strong Aftermarket Support: There is an extensive range of performance enhancements available, such as ECU tuning, turbo chargers, and heavy-duty components, which allow extensive customization and power gains.

Longevity and Durability: With proper maintenance, it’s common for these engines to be well over 300,000 miles (500,000+ km), so it is an investment that will last for the long term on both commercial and private use.

Disadvantages:

Complex Emissions Systems: Features like the EGR, DPF, and SCR systems add complexity and maintenance cost. They can also contribute to performance issues if not properly cared for.

Electronics and ECM Sensitivity: Certain model years (especially mid-2010s) have a bad reputation for faulty engine control modules (ECMs) and sensor fault problems, which require special diagnosis and skillful service.

Common Fault Codes: While most are harmless, the 6.7 is infamous for cycling frequent warning lights due to its extremely sensitive sensors and strict emissions controls. This can be disconcerting to inexperienced diesel owners who don’t have diagnostics tools or mechanical skill.

Final Words

It’s only the start of knowing the issues, using good parts and quality repair methods is the key to actually prolonging your 6.7L Cummins engine’s life.

If you want a trusted Cummins parts supplier, Longshine is your best choice. We offer high-quality Cummins engine components and can help you determine the most appropriate solutions for your applications. Please feel free to contact us for more product information and cooperation opportunities.