Product Description

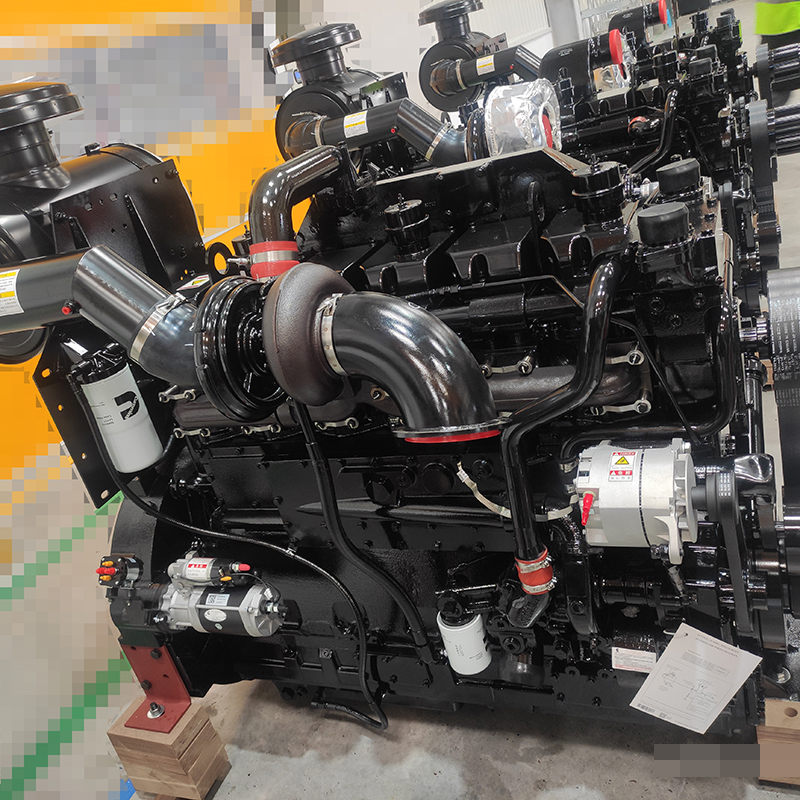

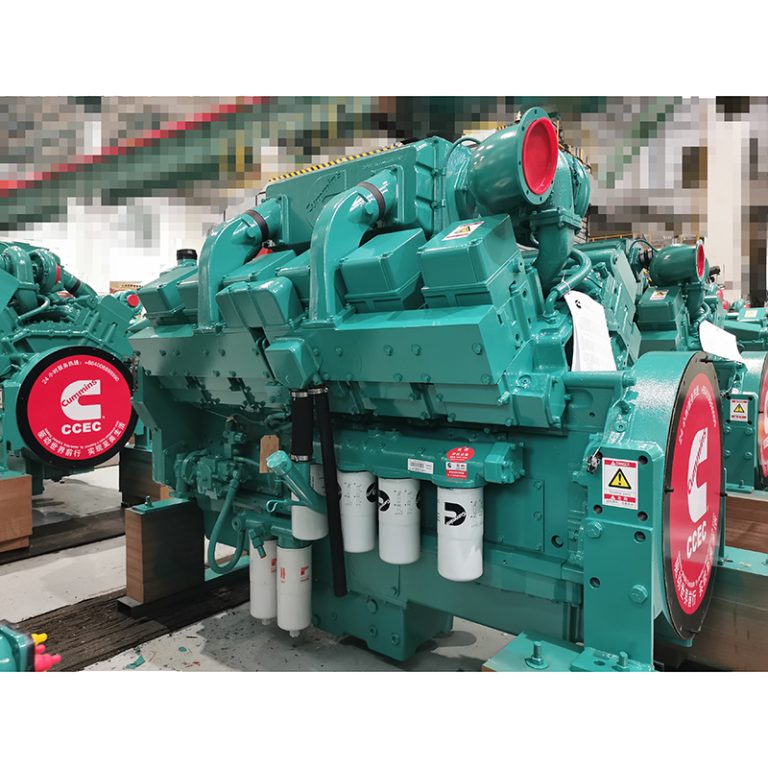

Cummins KTA19-G2 is a genuine 19.0-liter inline-6 diesel engine specifically designed for generator set applications. Delivering 400 kW prime power (~536 HP) and 440 kW standby power (~590 HP), it provides reliable, continuous, and stable electricity generation for industrial, commercial, and standby power needs. With Cummins’ proven engineering, the KTA19-G2 ensures long service life, fuel efficiency, and low maintenance costs, making it ideal for demanding operational environments.

Cummins KTA19-G2 Engine Technical Specification Sheet

| Parameter | Specification |

| Engine Model | KTA19-G2 |

| Cylinders / Configuration | 6-cylinder inline, 4-stroke diesel |

| Displacement (L) | 19.0 L |

| Bore × Stroke (mm) | 159 × 159 |

| Air Intake Method | Turbocharged and Aftercooled |

| Compression Ratio | 13.9:1 |

| Rated Speed (rpm) | 1500 rpm (50 Hz) or 1800 rpm (60 Hz) |

| Prime Power | 400 kW @1500 rpm (≈536 HP) |

| Standby Power | 440 kW @1500 rpm (≈590 HP) |

| Max. Torque (N·m) | 2800 N·m @1500 rpm |

| Cooling System | Water cooled (closed circuit); engine block coolant 28 L; with radiator 70 L |

| Fuel System | Cummins PT Fuel System |

| Fuel Consumption | 200 g/kWh at full load |

| Lube Oil Capacity (L) | Oil pan 54 L (standard) |

| Net Weight (kg) | 1850–1900 kg (without radiator) |

| Dimensions L×W×H (mm) | 2200 × 1100 × 1600 (engine only) |

| Emission Standard | Non-road Tier 0 / Stage 0 |

| Starting System | 24 VDC electric starter |

Cummins KTA19-G Series Engine Core Parameters

| Parameter | KTA19-G2 | KTA19-G3 | KTA19-G4 | KTA19-G5 | KTA19-G6 | KTA19-G8 |

| Rated Power | 440-550 hp | 500-600 hp | 550-700 hp | 600-750 hp | 700-850 hp | 800-950 hp |

| Displacement | 18.9 L | 18.9 L | 18.9 L | 18.9 L | 18.9 L | 18.9 L |

| Bore × Stroke | 159×159 mm | 159×159 mm | 159×159 mm | 159×159 mm | 159×159 mm | 159×159 mm |

| Compression Ratio | 14.5:1 | 14.5:1 | 14.5:1 | 14.5:1 | 14.5:1 | 14.5:1 |

| Air Intake Method | Single Turbo | Single Turbo | Single Turbo | Single Turbo | Dual Turbo | Dual Turbo |

| Fuel System | PT Fuel System | PT Fuel System | PT Fuel System | PT Fuel System | PT Fuel System | PT Fuel System |

| Max Torque | 1800-2200 N·m | 2000-2400 N·m | 2200-2600 N·m | 2400-2800 N·m | 2800-3200 N·m | 3200-3600 N·m |

| Rated Speed | 1500-2100 rpm | 1500-2100 rpm | 1500-2100 rpm | 1500-2100 rpm | 1300-1900 rpm | 1200-1800 rpm |

| Fuel Consumption | ≤195 g/kWh | ≤195 g/kWh | ≤195 g/kWh | ≤190 g/kWh | ≤185 g/kWh | ≤180 g/kWh |

| Oil Capacity | 38-42 L | 38-42 L | 38-42 L | 38-42 L | 45-50 L | 50-55 L |

| Cooling System | Standard water cooling | Standard water cooling | Enhanced water cooling | Enhanced water cooling | Dual-loop water cooling | Dual-loop water cooling |

| Typical Applications | Generator sets, marine auxiliary power,power station | |||||

Features & Benefits

- Reliable Power Output – 400 kW prime power and 440 kW standby power for continuous or emergency generator operation.

- Durable Construction – 6-cylinder inline, 4-stroke, water-cooled engine with reinforced components for extended life.

- Efficient Fuel System – Cummins PT (Pressure-Time) fuel injection with turbocharging and aftercooling ensures precise combustion and fuel economy.

- Compact & Serviceable Design – Engine dimensions 2200 × 1100 × 1600 mm, net weight 1850–1900 kg, easy to install and maintain.

- Fuel Efficiency – 200 g/kWh at full load, reducing operational costs.

Typical Applications

- Industrial and commercial generator sets

- Standby power systems for hospitals, data centers, and infrastructure

- Marine generator sets requiring reliable continuous operation

- Remote or off-grid power systems

- Any application demanding continuous, heavy-duty, reliable power output