Common Cummins PT Injector Problems and How to Fix Them

Cummins PT (Pressure-Time) fuel injectors are essential parts of older Cummins diesel engines like 5.9L 12V and Big Cam engines, where these mechanical injectors deliver fuel based on pressure and time to ensure efficient combustion. Unfortunately, like any component on any vehicle, PT injectors may develop issues over time.

Role of Cummins PT Injector

Unlike modern electronic injectors, which rely on electronic fuel delivery methods like those seen today, PT systems use mechanical fuel delivery mechanisms instead, making them both rugged and simple–though dependent upon regular maintenance to keep working at peak performance.

How PT Injectors Work

Fuel Delivery: The PT pump supplies pressurized diesel to the injectors through their fuel rails.

Timed Injection: Each injector opens at an exact moment during the combustion cycle, controlled by engine camshaft timing.

Self-Metering Design: The injector’s flow rate is determined by two factors – fuel pressure (regulated by the PT pump) and how long its nozzle remains open (controlled by camshaft).

Why PT Injectors Matter

Durability: No electronics means less chance for failure under challenging conditions

Tunability: Adjusting fuel pressure and injector pop-off settings can be used to optimize power and efficiency.

Legacy Support: Many vintage Cummins engines rely on well-maintained PT injectors for reliable operation.

Mechanical devices like fuel injectors can become worn over time due to wear, contamination, and pressure-related issues, so keeping them clean, adjusted properly, and leak-free for peak diesel performance is absolutely critical.

The most frequently reported PT injector issues and how to repair them follows.

Common Cummins PT Injector Problems

Cummins PT injectors are known for their durability and performance; however, as with any mechanical component they will wear down over time. Knowing the most frequently encountered issues will allow you to detect issues early and save yourself costly repairs later. Below are five commonly seen PT injector issues with explanations from Cummins:

1. Fuel Leakage from Seals or O-Rings

Fuel leakage is an often encountered problem, often the result of worn or damaged O-rings and seals within an injector assembly. Over time these rubber components become worn due to heat, pressure and chemical exposure and when they break they allow fuel to escape externally or leak internally disrupting injector function and potentially leading to fire hazards or poor injector timing or delivery issues. When this occurs a smell of fuel or visible evidence of fuel may indicate this is occurring and immediate inspection is required – replacing affected seals or O-rings often fixes this issue quickly and reliably.

2. Injector Nozzle Coking

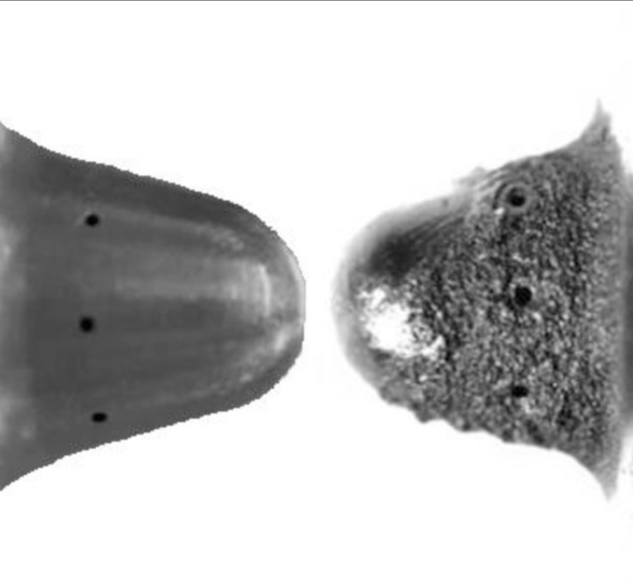

Over time, carbon deposits may form on the tips of injector nozzles–a condition known as coking. These deposits result from incomplete combustion or inferior fuel quality and clog the openings in the injector nozzles, disrupting fuel atomization and spray pattern which in turn results in inefficient combustion leading to rough idling, black smoke production, poor fuel economy and engine performance decrease. Regular maintenance with premium grade fuel additives can reduce carbon buildup; for severe cases professional cleaning or replacement may be necessary.

3. Injector Sticking

PT injectors contain moving parts that must operate accurately for proper engine functioning, but varnish buildup, debris accumulation or fuel contaminants may cause the internal needle or valve to stick, leading to overfueling, misfires or uneven engine operation with symptoms like engine knock, smoke production, reduced power output or inconsistent idle. In such instances, professional ultrasonic cleaning or injector cleaner additives may provide relief; otherwise replacement may be required.

4. Low or Inconsistent Fuel Pressure

To function optimally, the PT system relies on maintaining an ideal range of fuel pressure. If it falls too low due to a weak pump, clogged filters, or air entering the system, injectors won’t deliver sufficient amounts of fuel causing hard starts, poor throttle response or stalling requiring diagnosis with a gauge and verifying that everything related to delivery system–from tank to injector–is functioning normally.

5. Improper Fuel Injection Timing

To ensure proper combustion, fuel must be injected at exactly the right moment. If timing is off due to worn camshafts, misadjusted timing settings or malfunctioning ECM signals, engine performance will suffer significantly; symptoms include poor acceleration, increased fuel consumption, white or gray smoke emission and rough running. Recalibration or replacement parts may be required depending on manufacturer specifications or software tools available – in extreme cases mechanical repairs could even be necessary.

How to Fix Cummins PT Injector Problems

Correct diagnosis and maintenance are key in resolving issues with Cummins PT injectors. Here are some commonly utilized solutions:

Clean the Injectors: If carbon build-up or deposits are hindering performance, remove the injectors and use a professional-grade cleaner to restore proper spray patterns and fuel atomization. This will restore proper spray patterns.

- Maintain and Replace Seals: Faulty O-rings and seals can lead to fuel leakage, so it’s essential that these components are regularly checked for signs of wear, cracking, or hardening if they exhibit these characteristics.

- Check Fuel Pressure: Low fuel pressure can result in misfires or poor performance from injectors, so use a pressure gauge to test the system and inspect fuel pumps, lines, and filters for any restrictions or damage.

- Adjust Injection Timing: Improper timing can have detrimental effects on fuel efficiency and engine response. Follow Cummins specifications when making necessary adjustments or resets to injection timing – special tools may be required depending on what work needs doing.

- Test and Calibrate: Use diagnostic equipment to perform tests on injectors to ensure proper operation. Sticky or malfunctioning injectors may require recalibration or, in more serious instances, replacement altogether.

- Consult a Professional: For complex or ongoing issues, it is often beneficial to seek assistance from an authorized Cummins technician. Their extensive expertise and diagnostic tools allow them to effectively address deeper mechanical or electronic issues quickly.

Need to Replace Your Cummins PT Injector?

PT injector issues cannot always be remedied through cleaning and adjustments alone, replacement may be the answer. Although OEM Cummins injectors provide guaranteed compatibility, they can be costly. As an economical and durable alternative, many diesel enthusiasts and fleet operators turn to high-quality aftermarket options like Longshine for cost-effective yet long-term performance solutions.

Why Select Longshine PT Injectors?

- Our precision engineering builds injectors to meet or surpass OEM specifications, guaranteeing fuel delivery and combustion at optimal levels.

- Longshine Injectors offer budget-conscious solutions without compromising reliability for rebuilds or fleet maintenance applications.

- Each injector undergoes rigorous bench testing for correct pop pressure and spray pattern before shipping

- For maximum performance in various Cummins engines, including 5.9L 12V, 8.3L, and Big Cam models. Luckily, they’re compatible too!

Longshine offers high-flow nozzles to enhance performance upgrades and increase atomization for increased power and efficiency.

Remember: Always review injector specs and test new units prior to installation to avoid engine issues. Regardless of whether you opt for OEM or Longshine injectors, proper maintenance will help extend their longevity.